Going all out on productivity? Achieve a sustainable competitive advantage with ECO3's Expert Loader – a compact pallet loader for full prepress automation up to 1,200 plates of uninterrupted loading.

Most Avalon 8-up platesetters can be combined with a single or multi-cassette autoloader for increased automation and productivity. For the high-end Avalon N8-90 engines, there’s a second option: the Expert Loader. This compact 8-up pallet loader comes in two models – the Expert Loader Fix and the Expert Loader Var.

EXPERT LOADER FIX

- Room for one pallet (1,200 plates)

- Plates: 740 x 605 to 1165x 950 mm (gauge 0.24-0.4 mm)

- 2 predefined plate sizes

- Optional addition of 1 cassette (100 extra plates)

EXPERT LOADER VAR

- Room for one pallet (1,200 plates)

- Plates: 740 x 605 to 1165 x 950 mm (gauge 0.24-0.4 mm)

- Automatic plate size detection

- Optional addition of 1 or 2 cassettes

- Optional extension unit (for a second pallet)

Full prepress automation

Let the Expert Loader do the heavy work for you! Outputting up to 70 plates per hour, and offering up to 1,200 plates of uninterrupted loading, this pallet loader boosts your process efficiency while it excludes the risk of damage.

Plates are safely loaded from the emulsion side through suction cups, while double sheet detection reduces errors and unnecessary interruptions. Interleaves are automatically disposed of into a large trolley with a capacity of 400 m of paper.

The Expert Loader Fix works with maximally two predefined plate sizes. It is possible to add an extra cassette with a capacity of 100 plates. The Expert Loader Var automatically detects the plate sizes, so there is no need to predefine them. Optionally, up to two extra cassettes with a capacity of 100 plates can be added. Moreover, the Expert Loader Var can be equipped with an extension unit containing an extra pallet of 1,200 plates, catering to even the highest productivity demands.

Convenience is key

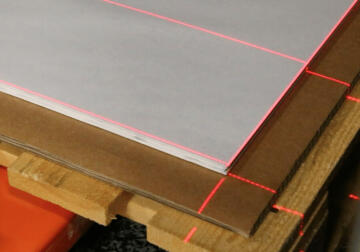

Trust the Expert Loader to load your plates directly from the pallet to the CtP engine. The only thing you have to do is drive in the pallet through the accessible loading gate on the left or right – the choice is yours. Leave it up to the advanced laser lines to indicate the correct position of your pallet, and use the intuitive touch panel to control plate production.