Clean, deglaze and condition ink rollers to prevent plate blinding, interference from chemistries like calcium carbonate and increased pH and conductivity spikes in the fountain solution. Below are some easy-to-follow maintenance tips.

Tip 1

Regular maintenance of dampening water, feed lines and circulators prevents contamination with slime, scum, ink or paper debris, keeping your press clean and enabling dampening rollers to accept ink and water. ECO3 product: ANTURA System Cleaner

Tip 2

Not all fountain solutions on the market have the same vulnerability for bio growth. Regular maintenance with ANTURA System Cleaner combined with ECO3’s ANTURA FOUNT AFS2 –(H) gives the best protection against bio-contamination on sheetfed presses. ECO3 product: ANTURA Fount AFS2

Tip 3

Plate blinding or loss of ink receptivity issues are mostly caused by improper roller care. It's best to remove all of these contaminants so that the rollers are clean and able to accept ink and water. ECO3 products: ANTURA Hybrid Rolkleen (universal cleaner) and ANTURA Ink Stripper (dried up ink remover)

Tip 4

The daily use of Reviverol Plus will keep your rollers and blankets in good condition. It will also minimize the need for extra cleaning.

Tip 5

ECO3’s cleaning agents will not only keep your presses in top condition. They are also environmentally the best choice, containing minimal to no hazardous raw materials.

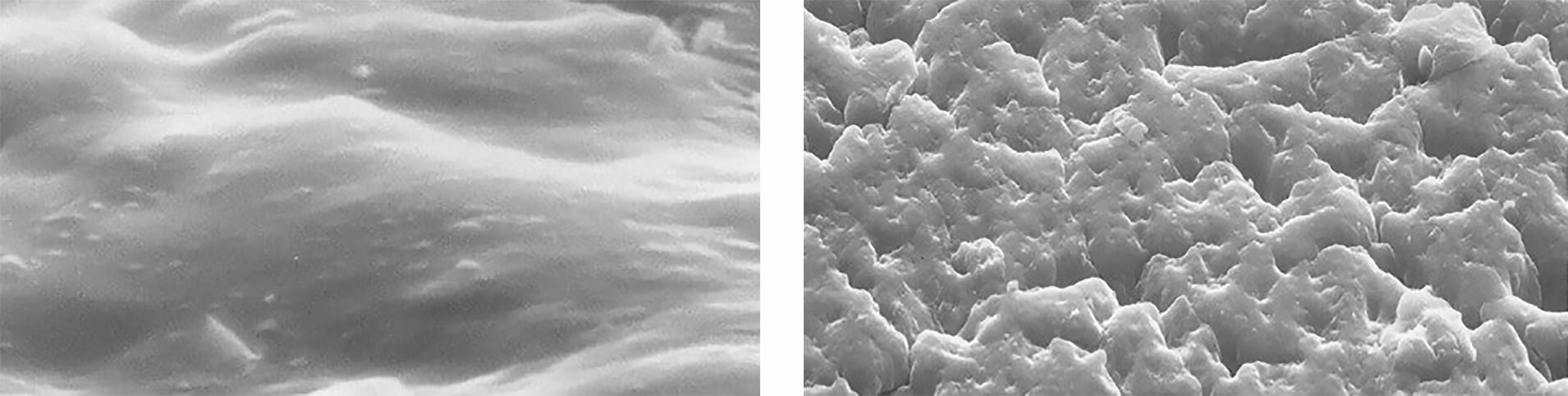

Example of glazed versus properly cleaned roller surface

The glazed look to the left is not the ideal surface to carry the ink and water emulsion down the roller train to the plate. Even more troubling is that the calcium, soap compounds and clays can easily ride down this roller surface to the printing plate, which will cause blinding. The goal is to clean the roller surface so that the proper transfer of ink and fountain solution can produce quality printing. A properly cleaned roller surface will look like the image to the right.