Are you looking for a negative-working plate that can be used for a wide range of purposes? This is it: the Aluva N serves all your printing needs from the smallest sheet-fed printer to the largest commercial operation. This versatility is a result of the unique combination of two technologies: UV-sensitive plate coating together with the grained and anodized aluminum substrate.

Expect outstanding performances, such as a stable ink/water balance, low dampening levels, and a fast start-up – even after a press stop-down. Integrate Aluva N with a computer-to-conventional-plate system by Lüscher, and exceed those expectations.

Benefits

UV Plate Technology

The Aluva N builds on ECO3’s experience and market leadership in analog and digital plate technology and combines advanced UV-sensitive plate coating with proven high-quality grained and anodized aluminum substrate. The result is a UV-sensitive plate uniquely made for computer-to-conventional-plate (CtCP) applications.

Optimum Press Performance

The plate delivers outstanding lithographic performance: fast start-up, low dampening levels, stable ink/water balance and fast restarts after press stop-downs. You benefit from easy handling with excellent durability and can achieve run lengths of 250,000 and more impressions (depending on the imaging and press conditions). Aluva N is a ‘no-bake’ solution for high run lengths. UV-ink capability is also given without baking.

High-quality Imaging

Aluva N is a negative-working plate with very high image contrast. Exposed on Lüscher’s proven XPose! UV setters, the plate is capable of 200 lpi (80 lpcm) AM and 25 μ FM imaging and is appropriate for a wide range of high-quality printing applications including stochastic screening.

Fast Exposure and Proven Plate Processing

The plate combines fast, accurate and wide-latitude plate exposure with simple and robust processing and there is a wide range of compatible processors available from different manufacturers. For best printing results and longest chemistry bath life, use Aluva N with ECO3’s Prima EN232 aqueous alkaline developer system.

| Characteristics | |

|---|---|

| Plate type | Negative-working high-speed UV offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | UV: 350-405 nm |

| Practical sensitivity | 58-78 mJ/cm² |

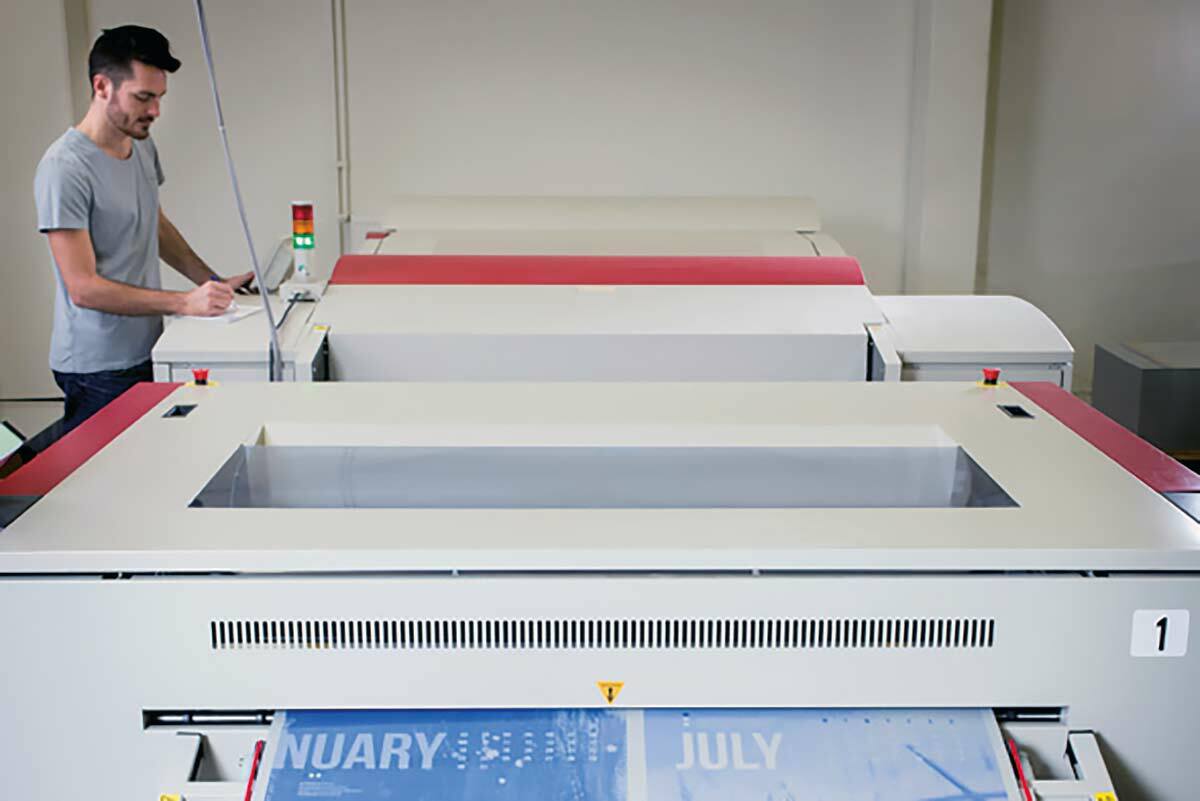

| Platesetters (CtcP) | Lüscher Xpose UV 230/260 / BasysPrint 400/800/VLF |

| Image contrast | Excellent, can be measured with all available densitometers and plate readers |

| Plate sizes (min. – max.) | 289×400 mm – 1500×2100 mm |

| Gauges | 0.15 mm, 0.30 mm and 0.40 mm (0.006″, 0.012″, and 0.016″). |

| 0.15 mm cannot be used with the Luscher PHS (plate handling system). | |

| Run length | 250,000 (baking improves the chemical resistance) |

| Processing | |

|---|---|

| Developer | EN 232 or EN 320 |

| Replenishment rate | 30-50 ml/m² |

| Bath life | 6 weeks or 5000 m² |

| Processor | We recommend a processor type with a least one brush, preferably two. |

| Environment | |

|---|---|

| Room lighting | Yellow/gold fluorescent tubes, windows covered with UV-protection film |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 70% RH |

| Storage conditions | 5-30° C, humidity 30-70% |