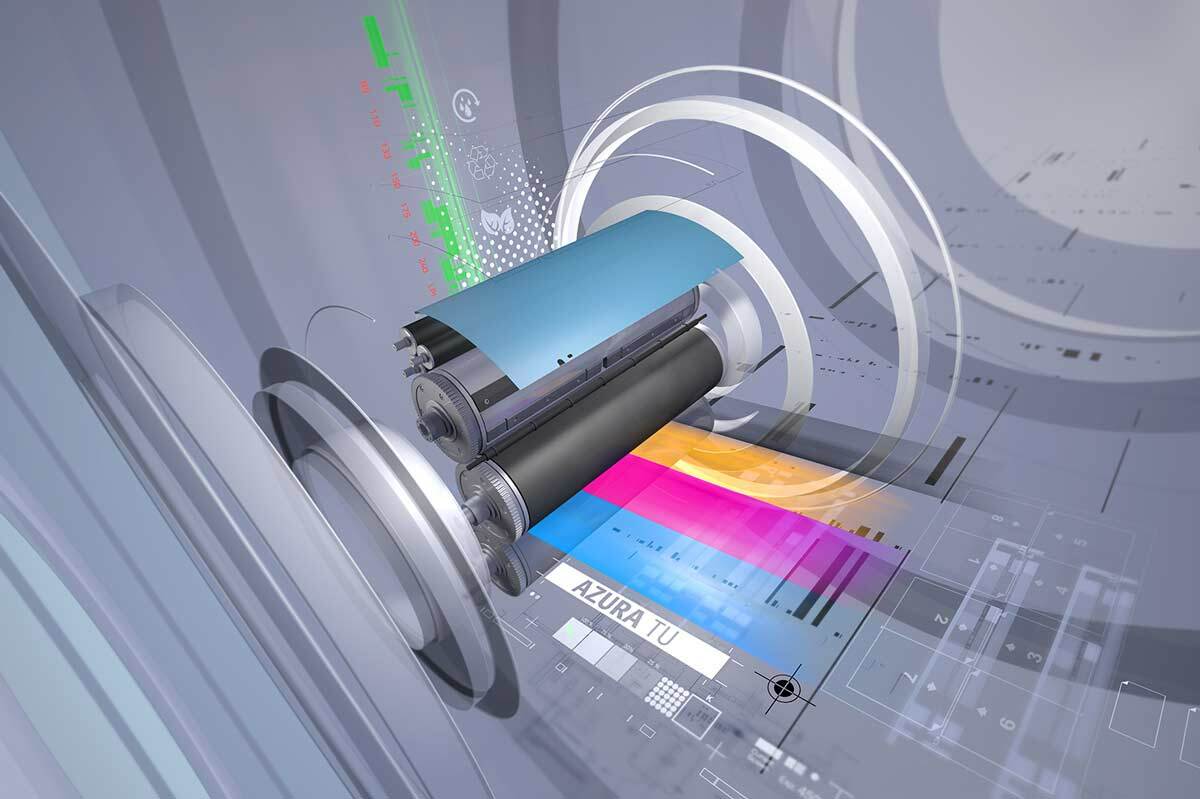

Designed for high-volume printing, simplified platemaking and uncompromising quality, Azura TU outperforms every other plate in its class. It is based on ECO3's patented ThermoFuse™ technology which creates a solid ink-accepting image, capable of printing 150,000 copies in one run.

Azura TU covers all sizes of sheetfed presses from B2 up to sheetfed format 6 and 7 for book and display printing. It also serves the fast-growing web-to-print applications that are printed on VLF sheetfed presses.

Not only does Azura TU raise your platesetter productivity. It also eliminates process variables and thus guarantees more reliable and consistent results. Another benefit to this technology is that it’s environmentally friendly, as chemicals are unnecessary and water consumption can be reduced by up to 95% compared to conventional prepress systems.

Benefits

True chemistry-free

As the image formation is a physical process, there is no need for developer or replenisher. No chemicals mean less disposal costs, a safer work environment and less waste.

Long bath life

In combination with the Azura CX clean-out unit, an extremely long gum bath life of up to 7,000 m² reduces equipment maintenance to an absolute minimum.

Water Saving

When switching from conventional processing to Azura TU, a water reduction of more than 95% can be realized, as no rinse water is required anymore.

Run lengths of up to 150,000 Copies

Azura TU puts the power of chemistry-free production into the hands of the most demanding sheet-fed commercial printers. Run lengths of up to 150,000 copies are now in reach with one single plate.

Fast Platemaking

A plate sensitivity of 160 mJ/cm² allows for more than 50 B1 plates per hour. Azura TU guarantees maximum CtP plate throughput on most commercial CtP platesetters.

High Quality

Azura TU is made of high-grade aluminum, allowing the delivery of prints with a razor-sharp image quality, up to 240 lpi.

Simplicity and stability

As the Azura TU plate is cleaned out with a simple pH-neutral gum, there are no changing processing parameters like temperature, conductivity or bath life. This results in a reliable and consistent image quality.

| Plate characteristics | |

|---|---|

| Plate type | Negative-working, chemistry free offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | 830 nm (thermal laser diode) |

| Plate sensitivity | 160 mJ/cm² |

| Platesetter compatiblity | Compatible with most common 830 nm external drum thermal platesetters |

| Image contrast | Excellent. The plates can be measured with all available densitometers and plate readers. |

| Plate sizes | Standard sheet-fed and web sizes |

| Resolution (depending on platesetter and screening algorithm) | Sublima: 1-99 % at 280 lpi at 2400 dpi FM 20 (Crystal Raster) at 2400 dpi |

| Gauges | 0.15 mm, 0.20 mm, 0.24 mm, 0.30 mm, 0.40 mm (0.006”, 0.008”, 0.010”, 0.012”, 0.016”) |

| Run length (depending on printing conditions) | Up to 150,000 dependent on press conditions Up to 10,000 with UV inks |

| Shelf life | 24 months |

| Cleaning | |

|---|---|

| Clean-out gum | Azura TU Gum Plus |

| Bath life | Up to 7,000 m² |

| Clean-out unit | Azura COU CX85, CX125, CX150 |

| Clean-out unit speed | 1.6 m/min. in CX85, CX125, CX150 |

| Environment | |

|---|---|

| Daylight resistance | Up to 48 hours in full daylight |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 70% RH |

| Storage conditions | Below 32 °C (90 °F), < 70% RH |

| Optimized ECO3 pressroom supplies | |

|---|---|

| Plate cleaner | ANTURA CtP plate cleaner |

| Overnight plate cleaner | ANTURA Clean Gum |

| Deletion pen | KP010 – KP011 – KP012 |

| Scratch remover | Reviva Plate |

| Fountain solution | Azura TU is compatible with all ECO3 fountain solutions |

| IPA | ANTURA IPA 100 |

| Roller and blanket wash | Azura TU is compatible with almost all ECO3 roller and blanket washes |