N95-VCF belongs to ECO3’s range of photopolymer offset plates for the newspaper industry. Like other violet offset plates, it is sensitized for visible lasers emitting at 405 nm, but instead of requiring a chemical developer for processing, it is designed for chemistry-free operation.

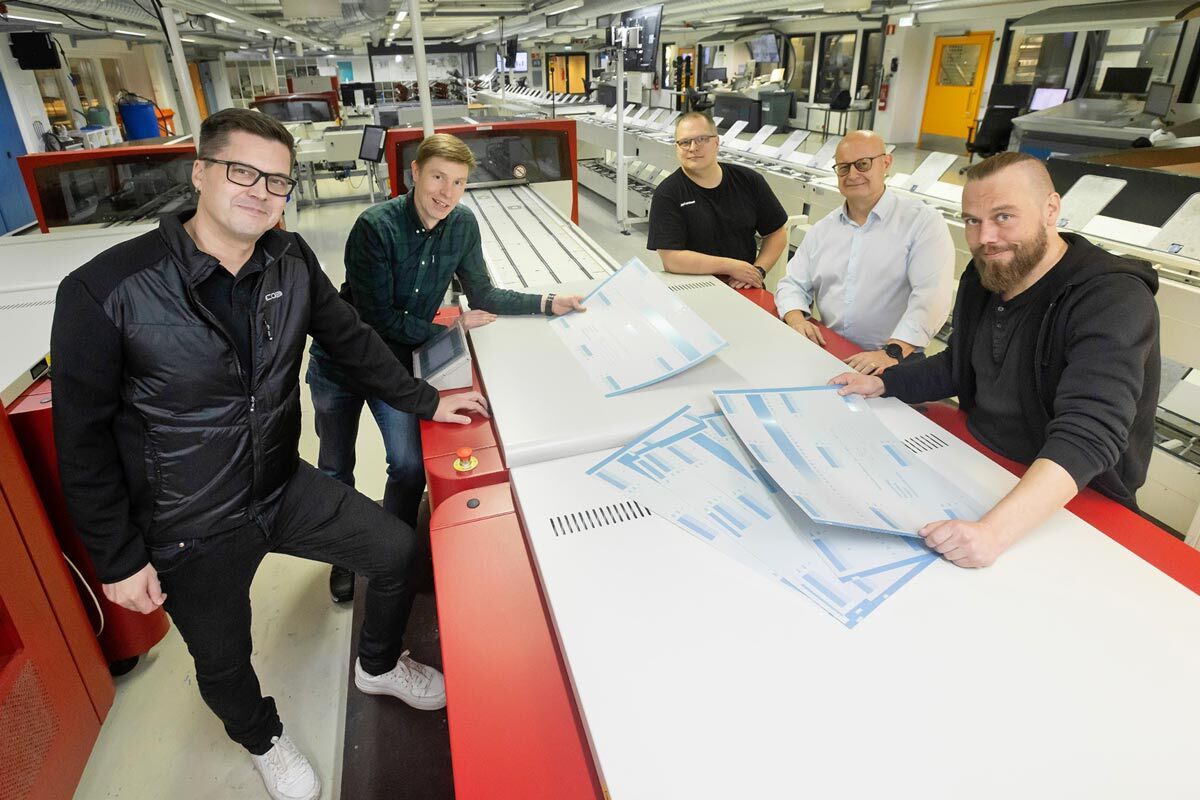

This chemistry-free plate works with all mainstream violet CtP units currently in use at newspaper print sites across the world. It is the most environmentally friendly plate on the market. Using a pH-neutral clean-out solution saves 100 percent of water and eliminates the use of developer and replenisher.

Benefits

Imaging & processing principle

During exposure, the violet-laser diode starts the polymerization of the image area, which is completed in the first section of the COU. Subsequently the plate is gummed with a dedicated plate gum, during which process the soft, unexposed non-imaged area is easily and cleanly removed. Once cleaned out, the plate is fully daylight-resistant.

Durable substrate

N95-VCF plates provide a solid foundation for consistent press performance. Advanced electrochemical graining and anodizing yield the reliability and robustness needed on a newspaper press and the durability required for long press runs. Scratch resistance is high.

High performance on press

Although a chemistry-free plate, press operators will readily accept it as it looks, feels and behaves as any other metal offset plate. With its high contrast, a quick visual check will reveal any possible errors (e.g. imposition). N95-VCF combines fast, accurate and wide-latitude plate exposure with chemistry-free processing, while ensuring predictable, consistent performance on press.

Easy maintenance and less waste

Chemistry-free solutions come with the benefit of a reduced environmental impact. No hazardous processing chemicals are used. The gum is pH-neutral and there is a substantial water saving. Just like with ThermoFuse solutions, violet chemistry-free offers major advantages in maintenance time.

Excellent resolving power

Suited for high-quality Sublima screening and SPIR@L screening

| Plate characteristics | |

|---|---|

| Plate type | Negative-working, high-speed, chemistry-free violet-laser offset plate |

| Coating | Photopolymer |

| Substrate | Electrochemically grained and anodized |

| Spectral sensitivity | 405 nm violet-laser diode |

| Practical sensitivity | 27 µJ/cm² |

| Platesetter compatiblity | Most violet platesetters |

| Image contrast | Good. Can be measured with all normal plate readers. |

| Plate sizes | All newspaper sizes, single and broadsheets |

| Resolution (depending on platesetter) | ABS: 2-97 % at 130 lpi |

| Sublima: 0.5-99.5% at 180 lpi | |

| Gauges | 0.20 mm, 0.30 mm |

| Run length | Up to 300,000 |

| Up to 100,000 for UV inks |

| Processing | |

|---|---|

| Clean-out gum | Violet CF GUM NP or Attiro GUM (for Attiro only) |

| Replenishment | Not required |

| Bath life (for Attiro) | Cleaning of Gum Section 1 required after 4,000 m2 (6.5 l) |

| Full cleaning required after 8,000 m2 (17.6 l) | |

| Processor and clean-out unit | Compatible with most polymer processors and clean-out units |

| Clean-out speed | 0.8-3.0 m/min depending on clean-out unit |

| Environment | |

|---|---|

| Room lighting | Yellow |

| Working conditions | Operating temperature 21-25 °C |

| Relative humidity 40-60 % | |

| Storage conditions | Temperature: < 30°C (86°F) |

| Relative humidity: 40 – 60 % |

| Recommended ECO3 pressroom supplies | |

|---|---|

| Gums | Violet CF Gum |

| Attiro Gum | |

| Baking gum: Not applicable | |

| Plate correction pen (for unbaked plates) | Polymer deletion pen |

| Plate Cleaner | Standard: ANTURA CtP Plate Cleaner |

| Cleaning gum: ANTURA CleanGum | |

| Rehardener | ANTURA Water Conditioner |

| Fountain Solutions | Sheetfed: Not applicable |

| Heatset: Not applicable | |

| Coldset: ANTURA Fount CS Plus / ANTURA Water Conditioner | |

| Rehardener: RC611 | |

| Roller and blanket washes | XTRAWASH Plus 40 & 60 |