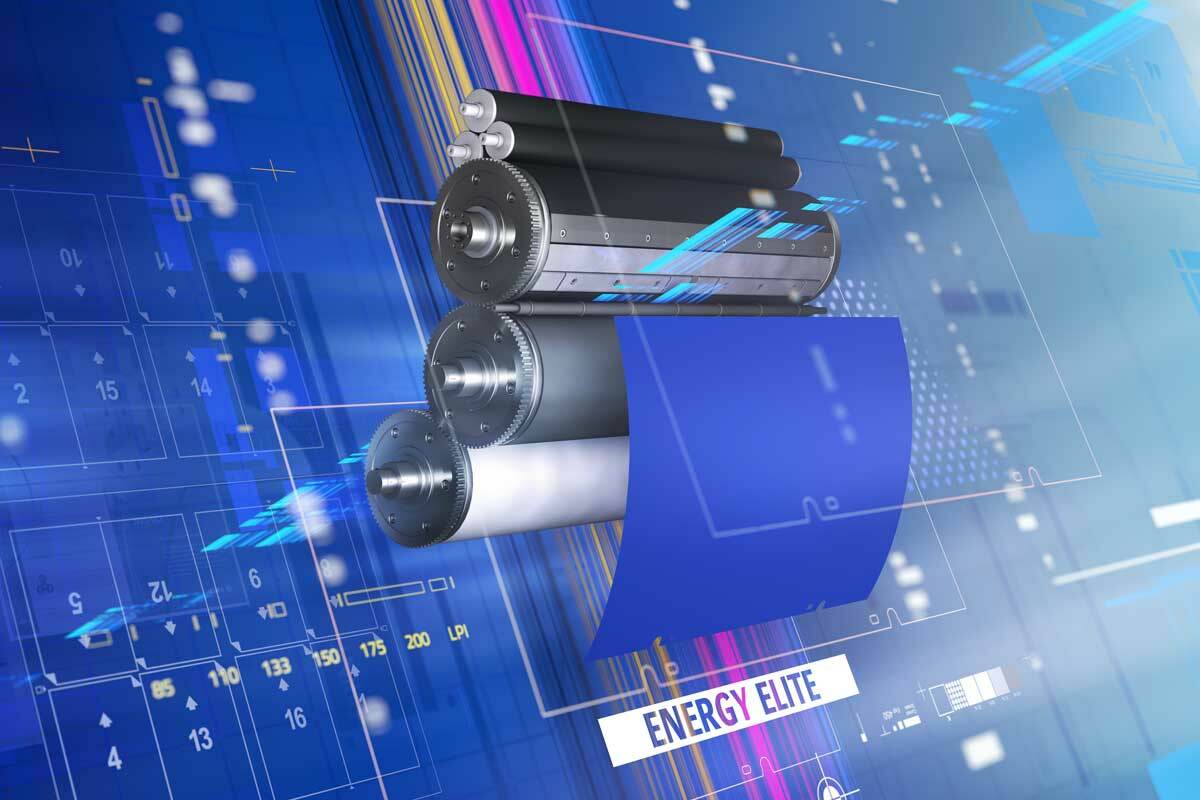

Energy Elite is an advanced, no-bake thermal plate technology. It’s fully compatible with UV and metallic inks and eliminates the need for baking, saving you on space and energy. It achieves runs up to 350,000 and, in harsh environments, up to 100,000 copies.

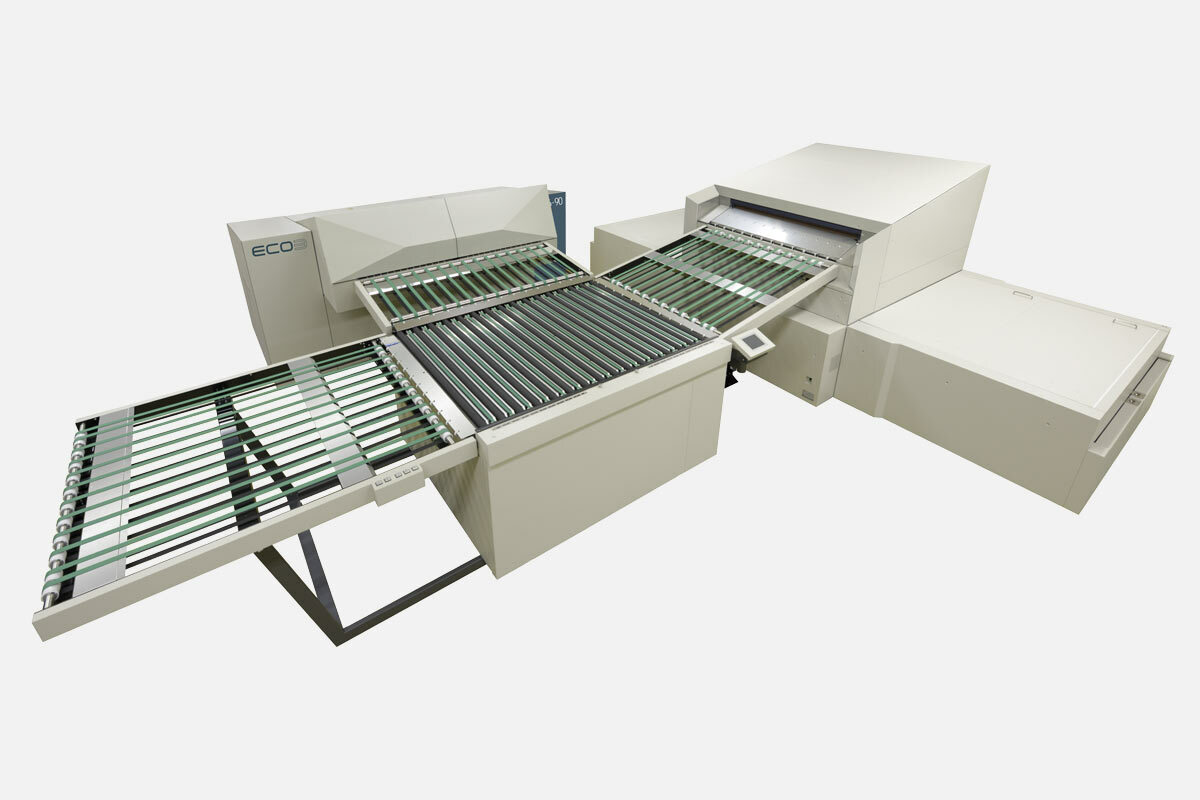

Energy Elite plates work seamlessly with all leading 830 nm thermal CtP systems. They use their own specific Energy Elite Improved developer, which ensures a long bath life, low chemistry consumption and clean processing.

Benefits

No-bake technology

Energy Elite’s double-layer technology uses a highly chemical-resistant second layer for long-run performance without the need for post-baking. This plate achieves runs up to 350,000 copies and, in harsh environments (e.g. UV and metallic inks), up to 100,000 copies. Its baking capability allows these run lengths to be further increased by 50 to 100%.

High-quality imaging

Energy Elite is a positive-working printing plate that’s daylight-safe and boasts excellent image contrast. ECO3’s advanced double-layer coating technology offers you a 1 to 99% imaging capability at 200 lpi.

No compromise on press

The use of ECO3's Flat Substrate Technology guarantees the widest latitude on press without compromising on performance. This yields low dampening levels, stable ink/water balance and excellent lithographic performance on press, including fast start-ups, even after press stop-downs.

Suitable for long runs

Energy Elite plates ensure robust, dependable press performance under a wide range of aggressive press conditions, without the need to post-bake. This results in a significant reduction of costs and energy consumption. The Energy Elite Developer system assures long chemistry bath life and minimizes processor cleaning.

| Plate characteristics | |

|---|---|

| Plate type | Positive-working, thermal offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | 830 nm (thermal laser diode) |

| Practical sensitivity | 115 mJ/cm² |

| Platesetter compatiblity | Compatible with all 830 nm platesetters |

| Image contrast | Excellent, can be measured with all available densitometers and plate readers |

| Plate sizes | Length: 450-2080 mm width: 480-1590 mm |

| Resolution (depending on platesetter) | ABS: 1-99% at 200 lpi at 2400 dpi |

| Sublima: 1-99% at 280 lpi at 2400 dpi | |

| FM 20 µm | |

| Gauges | 0.15, 0.20, 0.24, 0.30, 0.35 and 0.40 mm (0.006, 0.008, 0.010, 0.012, 0.014 and 0.016″) |

| Run length | 350,000 (UV inks: 100.000) |

| Processing | |

|---|---|

| Developer | THD200 developer (THR200 replenishment) |

| Replenishment rate | 50-80 ml/m² and 50-80 ml/h |

| Bath life | 4000 m² |

| Processor | All thermal plate processors |

| Environment | |

|---|---|

| Room lighting | Daylight |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 70% RH |

| Storage conditions | Below 32 °C (90 °F), <70% RH |

| ECO3 optimized pressroom supplies | |

|---|---|

| Plate cleaner | ANTURA CtP Plate Cleaner |

| Washout gum | ANTURA CleanGum |

| Machine finisher | Unifin Plus |

| Baking gum | RC510 |

| Fountain solutions | Energy Elite is compatible with all ECO3 fountain solutions |

| IPA | ANTURA IPA 100 |

| Roller and blanket washes | Energy Elite is compatible with all ECO3 roller and blanket washes |