Unlock the full potential of your commercial printing business with the Avalon VLF computer-to-plate (CtP) engines. Handling plates of up to 2280 × 1600 mm, and achieving a maximum throughput speed of 70 B1 plates per hour, these thermal platesetters are unique among their kind and prove themselves in productivity and flexibility. Simply select the engine that suits your needs in terms of plate size, throughput speed and features, and start boosting your business.

The Avalon VLF series comes in different levels of automation to match your preferred workflow and available floor space yet consistently offers prime imaging quality. All Avalon C VLF platesetters use fiber-coupled thermal laser diodes, while the Avalon N series are equipped with Grating Light Valve (GLV) imaging technology.

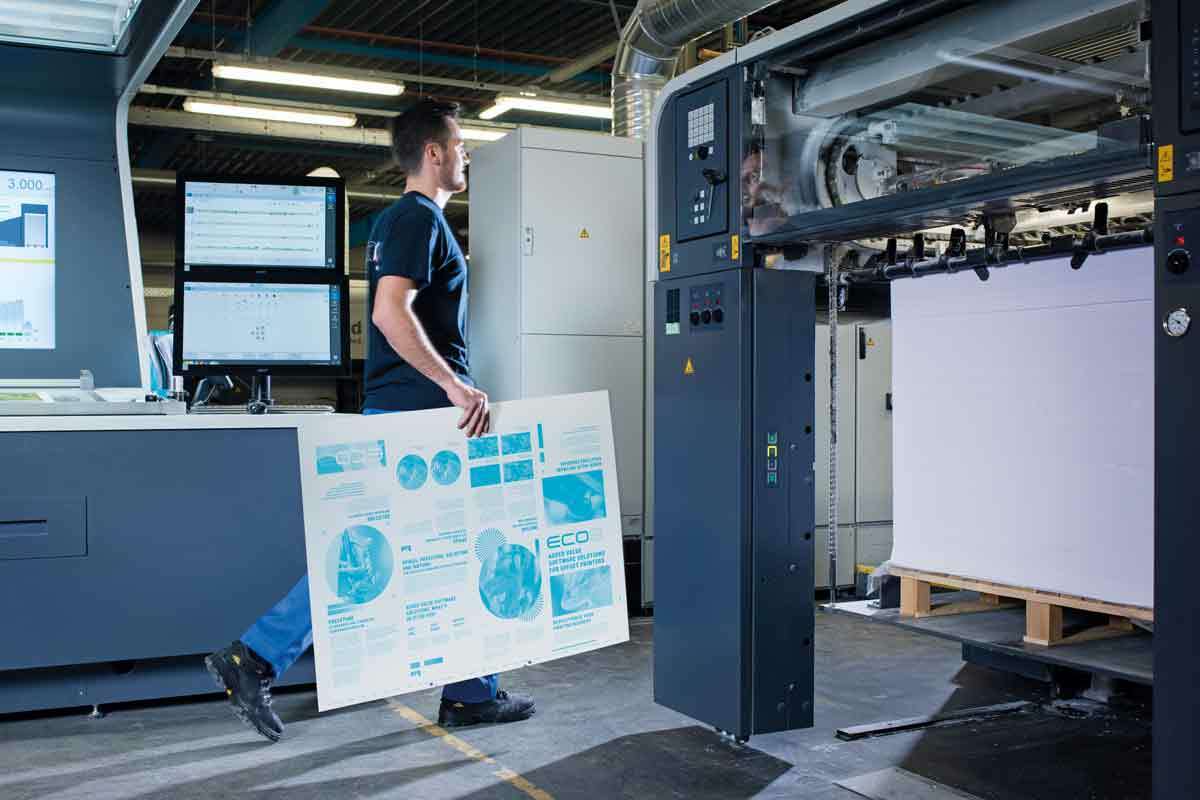

Boasting years of experience in very large format printing, ECO3 is the ideal partner to help commercial and packaging printing companies accomplish advanced process efficiency and automation, as well as cost control, in their prepress department.

Benefits

Industry-leading productivity

Thanks to their advanced laser diode technology and dual plate imaging, Avalon VLF engines offer best-in-class productivity and throughput speed. Combine them with the Energy Elite Eco printing plate, for example, to produce no fewer than 70 B1 plates per hour and still deliver premium-quality results.

More productivity-increasing options include dual plate loading and twin imaging, depending on the model. Most of the engines can also be upgraded with both a multi-cassette loader and a pallet loader. Plate loading of the Avalon VLF models can be automated using a custom-made plate loading robot.

Press punching

For those who need an extra-powerful productivity boost, there is a press punching system available for Avalon C and Avalon N VLF engines, significantly shortening make-ready time. By adding optional press punch blocks, imaged plates can be loaded straight onto presses with different punching, increasing make-ready efficiency.

Advanced integration

ECO3 has considered each element that affects CtP efficiency when integrating the Avalon series. The engine is an important link in the plate production chain, but it comes together with the plates, the plate processing, the digital workflow, screening and other additional software utilities. We will assist you in making the right technology decisions when creating a customized CtP solution.

Premium imaging quality

Avalon N VLF platesetters yield consistent, first-rate imaging quality of up to 340 lpi Sublima. All models are equipped with GLV technology for precise imaging, exceptional tonal accuracy and uniformity from job to job. So, whether you opt for a mid- or full-size engine, expect Avalon’s trademark excellence.

Integration with ECO3’s Apogee workflow

The Apogee prepress software makes it easy to schedule plate production. Fast plate remakes are just a click away.

16-up Avalon CtP systems

| Avalon C16-90 E, S & XT | |

|---|---|

| Imaging technology | - Avalon C16-90 E: 64 fiber coupled channels - Avalon C16-90 S: 96 fiber coupled channels - Avalon C16-90 XT: 128 fiber coupled channels |

| Laser type | 830 nm thermal laser diodes |

| Recording system | External drum |

| Press punch | Optional, max. 3 sets |

| Resolution | 1500/1800/2400/2540 dpi or 1200/1500/1800/2400 dpi or 1800/2400/2540/2800 dpi |

| Manual loading | Yes |

| Automatic (autoloader) | - Avalon C16-90 E ALS & Avalon C16-90 S ALS - Plate capacity: 100 plates (0.3 gauge) - Min./max. plate size: 450 x 370 mm (17.72 x 14.57") /1,524 x 1,185 mm (60 x 47.24") - Weight: 300 kg (661 lb) - Size (W x D x H): 2,280 x 3,070 x 1,200 mm (89.76 x 120.87 x 47.24") |

| - Avalon C16-90 EL XL FIX/VAR - Plate capacity: 1,200 plates (0.3 gauge) - Min./max. plate size: 660 x 745 mm (25.98 x 29.33") /1,425 x 1,915 mm (56.1 x 73.23") | |

| Manual unloading | Yes |

| In line unloading | Yes |

| Throughput (plates per hour @ 1,524 x 1,200 mm (60 x 47.24"), 2400 dpi, no punch) | - Avalon C16-90 E: 17 pph - Avalon C16-90 S: 24 pph - Avalon C16-90 XT: 29 pph |

| Max. plate size (along drum x around drum) | 1,524 x 1,200 mm (60 x 47.24″) |

| Min. plate size (along drum x around drum) | 450 x 370 mm (17.72 x 14.57″) |

| Thickness | 0.15 to 0.40 mm (6 to 16 mil) |

| Max. exposure size (along drum x around drum) | 1,524 x 1,185 mm (60 x 46.65″) |

| Weight | 1,560 kg engine; 100 kg filter housing |

| Size (imager) | - 2,300 x 3,010 x 1,200mm (90.55 x 118.50 x 47.24”) |

| Temperature range | Recommended: 18~28°C |

| Humidity range | 40%~60% RH (no condensation) |

| Power | 3- phase AC 380 V±5% 50/60 Hz, 5.3 kW |

| N16-90 E, S & XT | |

|---|---|

| Imaging technology | - N16-90 E: GLV 512 beams - N16-90 S: GLV 512 beams - N16-90 XT: GLV 1024 beams |

| Laser type | 830 nm thermal laser diodes |

| Recording system | External drum |

| Dual loading | n/a |

| Twin imager | n/a |

| Press punch | optional, max. 3 sets |

| Resolution | 1200, 2400 & 2540 dpi |

| Manual loading | yes |

| Semi-manual loading | n/a |

| Automatic (autoloader) | - N16-90 AL-M (TRIPLE L, R, L/R) - Plate capacity: 75 plates (0.3 gauge) or 60 plates (0.4 gauge) - Min./max. plate size: 650 x 550 mm (25.6 x 21.65") /1,470 x 1,180 mm (57.8 x 46.4") - Weight: 1,150 kg (2,514 lb) - Size: 3,150 x 3,215 x 1,715 mm (124 x 126.6 x 67.5") |

| Pallet loader | yes |

| Manual unloading | yes |

| In line unloading | yes |

| Throughput (plates per hour @ 1,030 mm (40.5") width) | - N16-90 E: 20 pph - N16-90 S: 37 pph - N16-90 XT: 46 pph |

| Throughput (plates per hour @ 1,448 mm (57") width) | - N16-90 E: 17 pph - N16-90 S: 29 pph - N16-90 XT: 42 pph |

| Max. plate size (along drum x around drum) | 1,470 x 1,180 mm (57.9 x 46.5″) |

| Min. plate size (along drum x around drum) | 650 x 550 mm (25.6 x 21.7″) * optional plate width between 570 and 624 mm cannot be used (size limitation) |

| Thickness | 0.2 - 0.4 mm (8 - 16 mil) *0.15 mm thickness can be used only for the optional min. size of 450 x 370 mm; 0.4 mm thickness plates can only be used when they are larger than 1030 x 770 mm |

| Max. exposure size (along drum x around drum) *dual model (with registartion punches – Leading edge grip: 8 mm; Trailing edge grip: 7 mm) | 1,470 x 1,169 mm (57.9 x 46.0″) |

24-up Avalon CtP systems

| Avalon C24-90 E/S/XT | |

|---|---|

| Imaging technology | - Avalon C24-90 E: 64-channel laser diodes - Avalon C24-90 S: 96-channel laser diodes - Avalon C24-90 XT: 128-channel laser diodes |

| Laser type | 830 nm thermal laser diodes |

| Recording system | External drum |

| Press punch | Max. 3 units |

| Resolution | 1500/1800/2400/2540 dpi or 1200/1500/1800/2400 dpi or 1800/2400/2540/2800 dpi (Other resolutions are optional) |

| Manual loading/unloading | Yes |

| Optional autoloaders | - C24-90 XT ALS - Plate capacity: 100 plates (0.3 gauge) - Min./max. plate size: 650 x 550 mm (25.6 x 21.65") /1,850 x 1,422 mm (72.83" x 56") - Weight: 375 kg loading table (772 lb) - Size (W x D x H): 3,865 x 2,700 x 980 mm (152.16 x 106.3 x 38.58") |

| - Avalon C24-90 EL XL FIX/VAR - Plate capacity: 1,200 plates (0.3 gauge) - Min./max. plate size: 660 x 745 mm (25.98 x 29.33") /1,425 x 1,915 mm (56.1 x 73.23") | |

| - Avalon C24-90 EL XL VAR + Extension - Plate capacity: 2,560 plates (0.3 gauge) - Min./max. plate size: 660 x 745 mm (25.98 x 29.33") /1,425 x 1,915 mm (56.1 x 73.23") | |

| Throughput (plates per hour @ 1,850 x 1,422 mm (70.86 x 55.98"), 2400 dpi) | - Avalon C24-90 E: 14 pph - Avalon C24-90 S: 19 pph - Avalon C24-90 XT: 23 pph |

| Min. plate size (along drum x around drum) | 650 x 550 mm (25.6 x 21.65”) |

| Max. plate size (along drum x around drum) | 1,850 x 1,422 mm (72.83 x 56”) |

| Thickness | 0.15 - 0.4 mm (6 - 16 mil) |

| Max. exposure size (along drum x around drum) | 1,850 x 1,407 mm (72.83 x 55.4”) |

| Weight | - 2,480 kg engine (5468 lbs) - 190 kg air pump box (419 lbs) |

| Size (imager) | 3,800 x 2,700 x 1,000 mm (149.60 x 106.3 x 39.37") |

| Temperature range | Environment: 18~28°C |

| Humidity range | RH: 40%~60%(non-condensing) |

| Power | 3- phase AC 380 V±5% 50/60 Hz |

| Avalon N24-90 S & XT | |

|---|---|

| Imaging technology | - Avalon N24-90 S: GLV 512 beams - Avalon N24-90 XT: GLV 1024 beams |

| Laser type | 830 nm thermal laser diodes |

| Recording system | External drum |

| Dual loading | Not available |

| Twin imager | Not available |

| Press punch | Optional, max 6 sets |

| Resolution | 1200, 2400 & 2540 dpi |

| Manual loading | Yes |

| Semi-manual loading | Yes |

| Automatic (autoloader) | Yes |

| Pallet loader | - N24-90 Pallet Loader - Plate capacity: 600 plates (0.3 gauge) - Min./max. plate size: 1,000 x 750 mm (39.4 x 29.5") /1,652 x 1,325 mm (65 x 52.2") - Weight: 800 kg (1,764 lb) - Size (W x D x H): 2,725 x 1,935 x 1,760 mm (107.5 x 76.2 x 69.3") |

| Manual unloading | Yes |

| In line unloading | Yes |

| Throughput (plates per hour @ 1,030 mm (40.5") width) | - Avalon N24-90 S: 34 pph - Avalon N24-90 XT: 46 pph |

| Throughput (plates per hour @ 1,448 mm (40.5") width) | - Avalon N24-90 S: 27 pph - Avalon N24-90 XT: 39 pph |

| Max. plate size (along drum x around drum) | 1,652 × 1,325 mm (65.0 x 52.2″) |

| Min. plate size (along drum x around drum) | 650 x 490 mm (25.6 x 19.3″) |

| Thickness | 0.2 to 0.4 mm (8 to 16 mil)* 0.4 mm (16 mil) is only available for plates larger than 900 mm x 770 mm |

| Max. exposure size (along drum x around drum) *dual model (with registartion punches – Leading edge grip: 8 mm; Trailing edge grip: 7 mm) | 1,652 × 1,313 mm (65.0 x 51.7″) |

40-up Avalon CtP systems

| Avalon N40-90 S & XT | |

|---|---|

| Imaging technology | GLV 1024 beams |

| Laser type | 830 nm thermal laser diodes |

| Recording system | External drum |

| Dual loading | Yes |

| Twin imager | Yes |

| Press punch | Optional, max 5 sets |

| Resolution | 1200, 2400 & 2540 dpi |

| Manual loading | Yes |

| Semi-manual loading | Yes |

| Automatic (autoloader) | - N40-90 AL-M - Plate capacity: 75 plates per cassette (0.3 gauge) or 60 plates per cassette (0.4 gauge) - Number of cassettes: 4 - Min./max. plate size: 500 x 550 mm (19.7 x 21.7") /2,280 x 1,600 mm (89.7 x 62.9") - Weight: 2,540 kg (5,599 lb) - Size (W x D x H): 3,365 x 4,123 x 1,850 mm (132.4 x 162.3 x 72.8") |

| - N40-90 AL-M (L,R) - Plate capacity: 75 plates per cassette (0.3 gauge) or 60 plates per cassette (0.4 gauge) - Number of cassettes: 4 - Min./max. plate size: 620 x 550 mm (25.6 x 21.7") /2,280 x 1,600 mm (89.7 x 62.9") - Weight: 2,600 kg (5,732 lb) - Size (W x D x H): 3,365 x 4,123 x 1,850 mm (132.4 x 162.3 x 72.8") | |

| Pallet loader | - N40-90 Pallet Loader (L,R) - Plate capacity: 600 plates (0.3 gauge) - Min./max. plate size: 800 x 550 mm (31.5 x 21.7") /2,280 x 1,560 mm (89.7 x 61.4") - Weight: 1,750 kg (3,858 lb) - Size (W x D x H): 3,415 x 2,120 x 2,075 mm (134.5 x 83.5 x 81.7") |

| Manual unloading | Yes |

| In line unloading | Yes |

| Throughput (plates per hour @ 1,030 mm (40.5") width) | - Avalon N40-90 S: 46 pph - Avalon N40-90 XT: 70 pph |

| Throughput (plates per hour @ 2,288 mm (89.7") width) | - Avalon N40-90 S: 24 pph - Avalon N40-90 XT: 34 pph |

| Max. plate size (along drum x around drum) | - 2,280 x 1,600 mm (89.7 x 62.9″) - dual loading: 1,060 x 1,600 mm (41.7 x 63″) |

| Min. plate size (along drum x around drum) | - 1,061 x 550 mm (41.8 x 21.7″) - dual loading: 650 x 550 mm (25.6 x 21.7″) |

| Thickness | 0.2 to 0.4 mm (8 to 16 mil) 0.5 mm (20 mil) optional |

| Max. exposure size (along drum x around drum) - with registration punches – leading edge grip: 8 mm; trailing edge grip: 7 mm) - without registation punches Leading edge grip: 5 mm; Trailing edge grip: 7 mm | 2,280 x 1,588 mm (89.7 x 62.5″) |

To streamline prepress workflow and boost productivity, Avalon VLF platesetters can be automatically loaded by a robotic plate loader. It is custom-built according to a printer’s exact needs and can simultaneously feed two plate production lines with a speed of up to 80 printing plates per hour, independent of plate size. The set-up is especially convenient for printers that need to handle multiple plate sizes (up to five).