ECO3’s latest screening technology & thermal polymer plate improves print quality & saves money

ColorDynamics Inc. is one of the largest full-service printers in the southwest, offering innovative graphic communications and turn-key services that exceed their clients’ expectations. The award-winning company serves the convenience store, direct mail, automotive, educational, food service, healthcare, manufacturing, publishing, retail, trading card, and utility segments.

Their approach combines decades of experience, insight, and wisdom in the printing industry and new, innovative solutions that delight the customer experience. So, when David Dey, vice president of manufacturing at ColorDynamics, heard that ECO3’s latest screening technology and thermal polymer plate could improve print quality and save money, he wanted to learn more.

ColorDynamics agreed to evaluate ECO3’s SPIR@L screening and the Energy Verve printing plate. SPIR@L harnesses dot gain requiring less ink, resulting in higher-quality images with the finest detail and brightest colors. Energy Verve answered ColorDynamics’ need for a robust thermal printing plate for demanding print conditions. The company serves a diverse clientele and prints on a wide variety of stock and board, coated and uncoated, with different finishes, all of which have significant variation. So, the team put SPIR@L and Energy Verve to the test.

A new way of thinking about dot gain

“SPIR@L offers a big shift in how we, as an industry, consider and manage dot gain,” explains Dey. “Instead of working to minimize dot gain, the SPIR@L concept works in reverse. SPIR@L screening provides the ability to use gain as a desired outcome. The concept of using gain to improve the final product, instead of controlling it to reduce the degradation of the final product, is counterintuitive and an intelligent switch in thinking.”

SPIR@L screening is simple but brilliant. The traditional dot is replaced with a more economical SPIR@L shape. This means it requires less ink to fill in the exact same space, resulting in a crystal-clear image every time.

We see a 10 to 20 percent reduction in ink which is substantial over the course of a year. It’s come without any decline in quality. The SPIR@L screening allows us to get the same vibrancy, richness, overall look and feel with substantially less ink.

David Dey, Vice President of Manufacturing - ColorDynamics

SPIR@L applies ink in a more controlled manner. The dot structure allows printing with a thinner ink film. Dey explains, “The SPIR@L dot structure is a flatter dot, which allows for controllable ink transfer with a wider range of acceptability and a greater level of consistency. We find that the ink interaction with the image screening increases the latitude for success. And that is a huge deal, especially in web printing when attempting to achieve the quality levels of sheetfed printing.” With SPIR@L, quality isn’t compromised regardless of press speeds, thus improving productivity while significantly reducing waste and overall costs.

SPIR@L and Energy Verve offer many positives for ColorDynamics

“For us, SPIR@L screening with the Verve plate means the sum of the two together is much greater than each part individually,” clarifies Day. “I believe SPIR@L and Energy Verve bring out the best in each other and optimize their effectiveness.”

Energy Verve is a durable, negative- working, thermal photopolymer plate specially designed for extreme conditions, such as printing on abrasive stocks or printing with UV inks or opaque white inks. Robust and highly sensitive, Energy Verve offers exceptional chemical and mechanical resistance with run lengths of up to 1 million copies without post bake while consuming 50% less energy.

Energy Verve reduces potential problems

“Energy Verve’s deep graining structure offers a better ink and water balance which is one of the biggest challenges with our previous plate, and thus, it reduces potential problems,” notes Dey. “From start-up to sellable sheet, we use less paper, less ink, have fewer challenges, less variability, and the process is more consistent. Printing at its core is a liquid-based operation. The more control you have over the liquids you’re using, the less opportunity for problems.”

Mastering print run variations

On the commercial side of the business, ColorDynamics prints marketing collateral and direct mail for many customers on both UV sheetfed and heatset web presses. They run a wide array of stocks and coatings, including substantial use of white ink, all of which increase potential variation in reproduction.

The number of variables creates a huge challenge for controlling color; it is critical to have stability and repeatability in the plate. We have an infinite number of combinations from print run to print run because of stock, both paper and synthetic, whether we print direct to the substrate or on a foundation that includes white ink and the addition of coatings and laminates that can alter the look of the color.

David Dey, Vice President of Manufacturing - ColorDynamics

Energy Verve helps simplify the process

Dey sums it up by explaining, “Energy Verve affords a higher level of consistency and also handles the variability with fewer outside manipulations from the printer. We can do more things with fewer changes across the board, and we can get to a very high quality that we couldn’t achieve with the previous products we used. ECO3 is a good partner with our business.”

The ColorDynamics team combines decades of experience, insight, and wisdom with the latest technological solutions to meet the ever-changing needs of their clients.

The combination of SPIR@L screening and Energy Verve has positively impacted ColorDynamics bottom line.

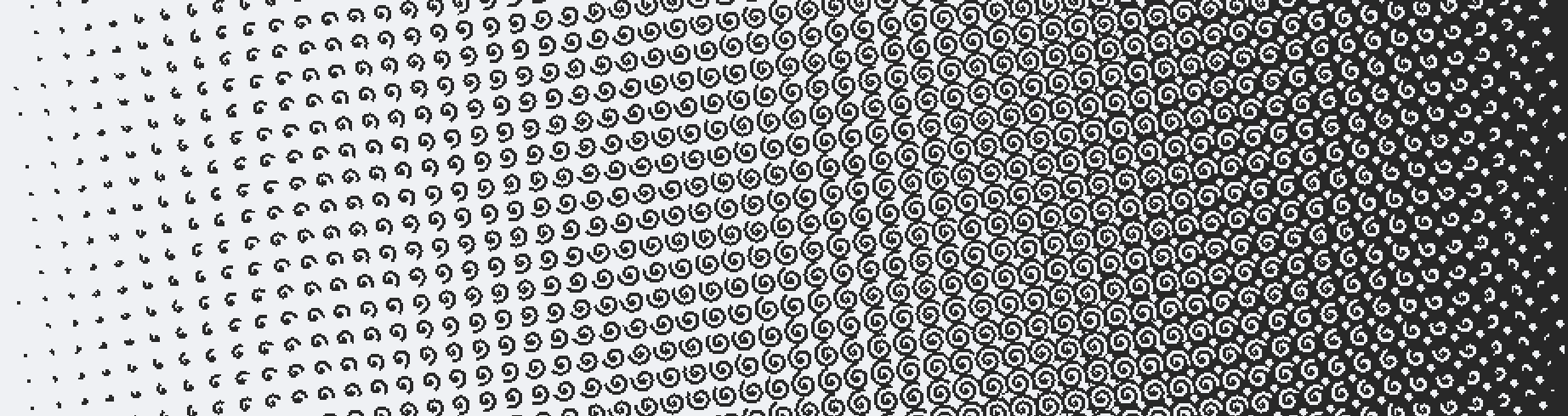

SPIR@L

This new screening technology replaces the traditional ink dot with more efficient shapes such as spirals. This has a positive impact on print quality and results in a crystal-clear image every time without effort.

Discover

Energy Verve

Energy Verve has it all: run lengths up to 1 million copies combined with both process and cost efficiency - the perfect choice for demanding printing jobs

Discover