With this new and patented print screening technology, ECO3 takes its focus on ecology, economy and extra convenience to the next level.

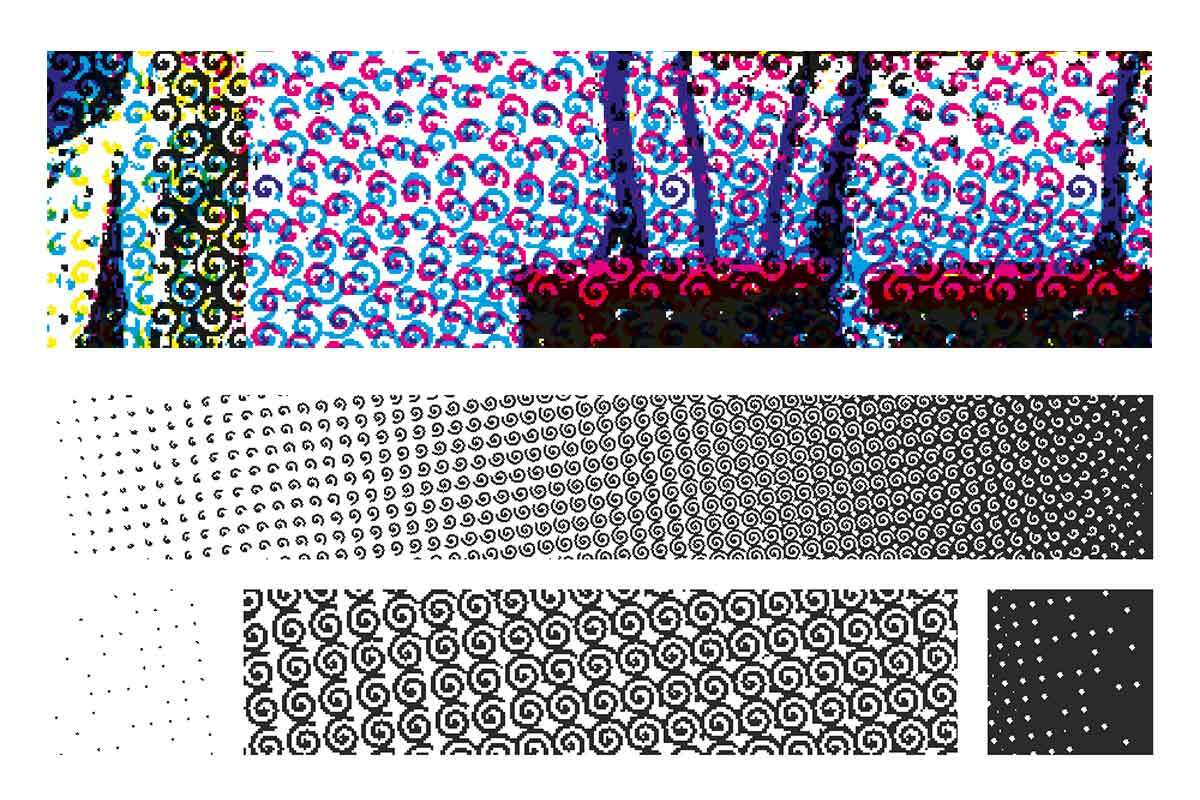

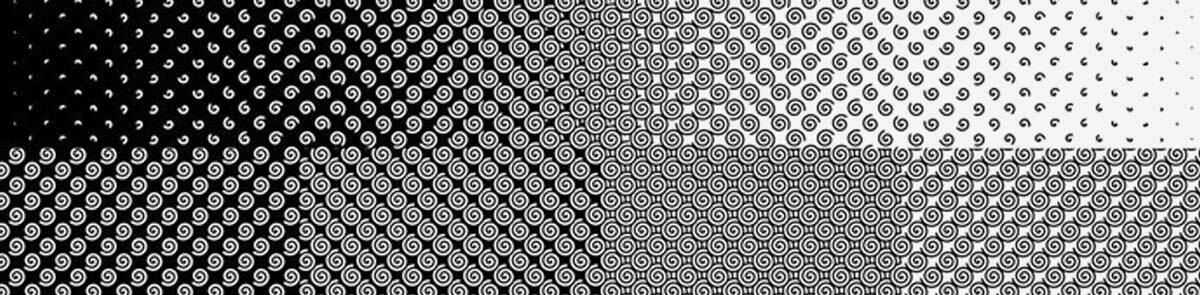

The concept is straightforward but all the more innovative: we replace the traditional ink dot with other more efficient shapes such as spirals. This has a positive impact on print quality and results in a crystal-clear image every time without effort. SPIR@L lets you hold a 1-99% dot, guaranteeing vibrant colors and reducing image slur. What’s more, it requires no expensive upgrades for your CTP or printing press.

SPIR@L screening is suitable for heatset, newspaper and packaging printing.

Benefits

Eliminates imperfections

No image slur: with SPIR@L, you get crystal-clear image rendering every time. No more costly reprints required!

All the advantages of a thinner ink layer

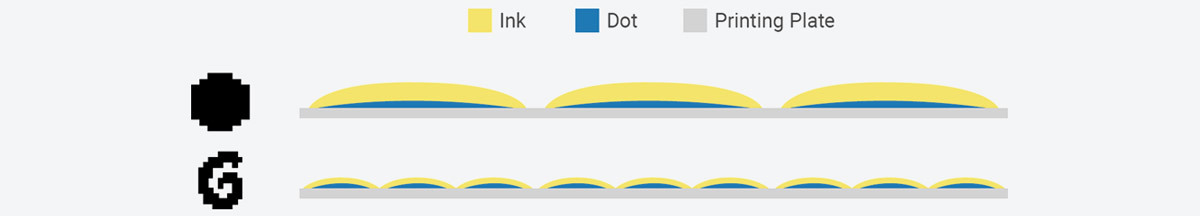

Thanks to the unique SPIR@L dot shape, less ink is required to fill in the exact same area. Next to saving ink, this speeds up drying and reduces see-through when printing on thin paper. As an added bonus, faster drying also reduces the occurrence of web breaks on web offset presses.

Improved production speed

With SPIR@L, presses can run faster without spraying the ink. This improves speed and productivity while significantly reducing your energy consumption and overall costs.

True blue

SPIR@L delivers a more pure color reproduction in the blue color range.

SPIR@L White Paper for commercial printers & newspapers

The SPIR@L white paper describes in detail how SPIR@L technology works, how it compares to other screening solutions and what its benefits are.

Request the white paperSPIR@L Datasheet for flexo

The SPIR@L data sheet for flexo gives a brief overview of how SPIR@L works and what the advantages are for brand owners, repro shops, trade houses, converters and flexographic printers..

Download the datasheetHow it works

The new SPIR@L technology begins the printing process by placing a modified minimum ink dot, created in a varying shape, such as a spiral.

Thanks to the solution’s smooth transition from positive to negative spirals and minimum white gap, the result is always a high-quality image in vibrant colors. You can set up SPIR@L according to your preferences: different curves and groove area thicknesses can be selected depending on the press and paper used to achieve high quality print at the lowest possible cost.

By replacing conventional dots with spiral shapes, the thickness of the ink layer is reduced. This leads to lower ink consumption and faster drying.