Use ECO3’s fountain solution ANTURA fount AFS2(-H) to reduce your sheet-fed press’ IPA dosage to 2-3% without much extra effort. Even a reduction to 0% is possible, albeit with a bit more adjustments on the press.

The main advantages

- Cost reduction

- Lower CO2 emission

- Excellent results in terms of toning

- Get to your first sellable sheet faster

How to proceed

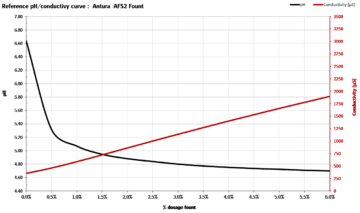

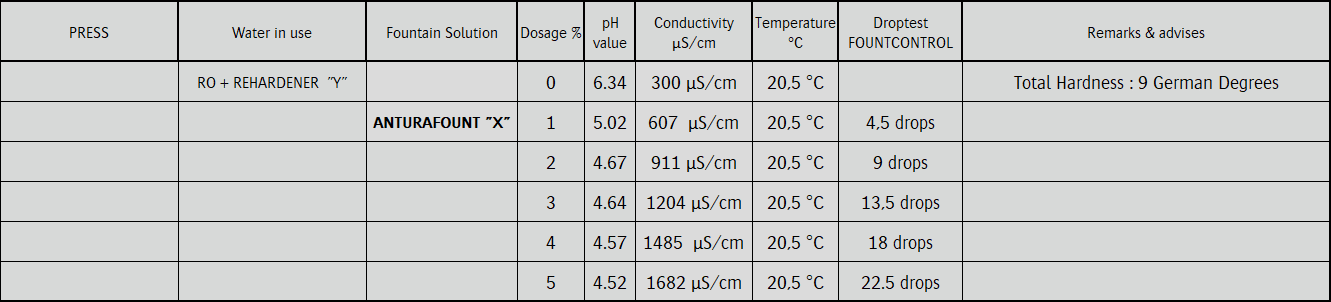

- Make a reference curve with ANTURA fount AFS2(-H). Use this as your guideline in dosing. Perform an extra fount control drop test. See the example reference curve.

- Empty the water tank (Technotrans/Baldwin etc.) and special filter device, clean the transfer case and then refill with 3-4% ANTURA fount AFS2(-H). Before you do this, adjust and decrease your dosage IPA from approx. 10% to 2 or 3%.

- Refill the water tank of the press until the circulation pump starts. After 5 minutes, empty again.

- Refill the press with 3 to 4% ANTURA fount AFS2(-H) and 2 or 3% IPA until the circulation pumps are working again and temperature is achieved.

- Before starting the press, you should control all settings of ink and dampening rollers against the plates on every unit involved.

- Dosage during IPA-free printing needs to remain very consistent. In the start-up phase (first week) regularly check pH and conductivity and compare with your reference curve!

- Print the first start-up sheet with this process water with reduced or no IPA.

- When printing without IPA or with a low IPA dosage, it is very normal that you need to raise the water level. You need to find the right water-ink balance again. When the water level nears 100%, then you definitely need to re-check the roller nips of the dampening roller system. Maybe you need to adjust the roller nips manually to get a slightly thicker water film on your plate. Make sure you see a mat water film on your plate while printing, and not a shiny one.

Give it a try!

Use voucher code ANTURA20L to request a free 20-liter canister of ANTURA fount AFS2.