Looking for higher speed, improved contrast and longer bath life? Then the chemistry-free Amigo TS digital plate is your companion.

Instead of traditional chemical processing, Amigo TS uses the physical ThermoFuse technology. This offers you simple platemaking with consistently high quality, as well as remarkable chemical resistance and processing latitude – plate after plate. Additionally, Amigo TS is more robust and faster than its predecessors.

This multi-purpose plate works on any suitable 830 nm thermal platesetter and can handle fluctuations in laser energy with virtually no effect on image quality. It works perfectly in daylight and tolerates a wide array of processing and exposure variations while still guaranteeing that same quality.

Benefits

Superior press performance

The inherent simplicity of platemaking with Amigo TS plates ensures that your pressroom is supplied with a steady stream of the highest quality plates. The proven technology used in this plate’s coating offers excellent chemical resistance, making Amigo TS plates suitable for a wide range of sheet-fed and web offset printing applications. Post-baking will increase the run length significantly. The specially developed ‘Flat Substrate Technology’ ensures optimized ink/water balance, clean-out and run length performance.

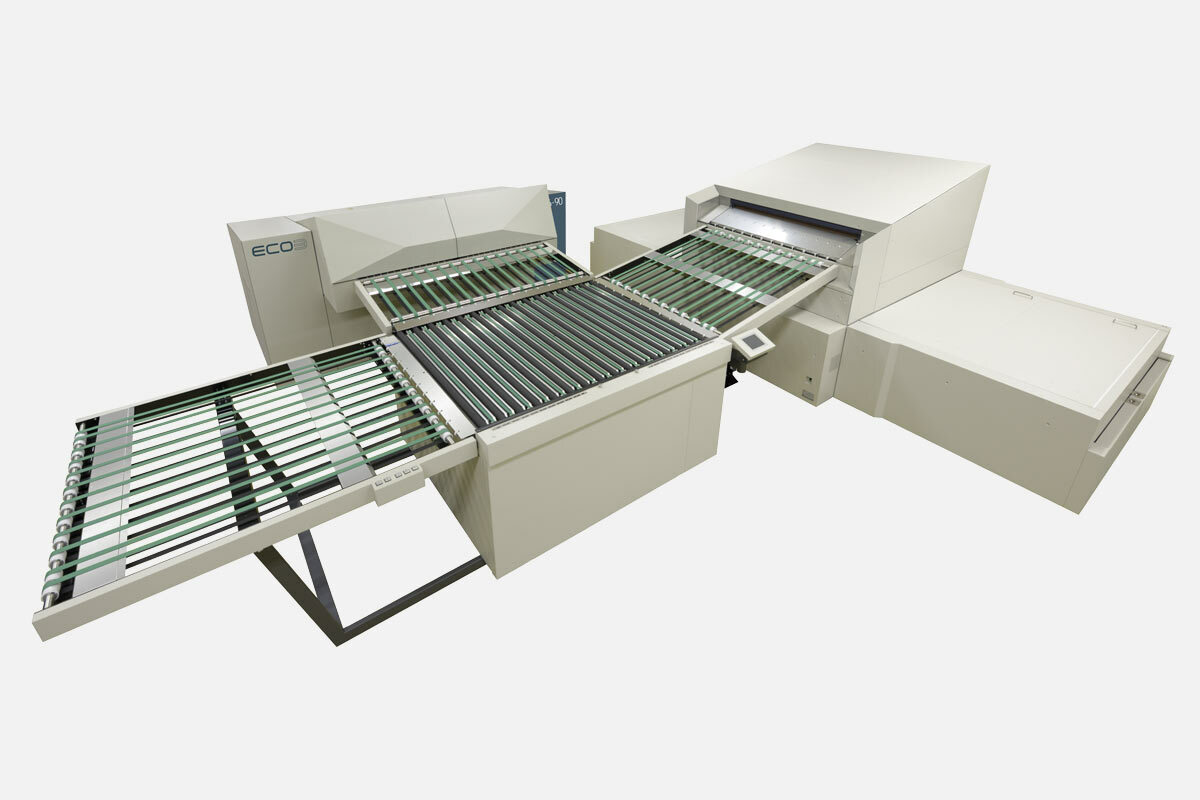

Simplified platemaking

Platemaking has never been this simple and straightforward. Amigo TS is tolerant to a broader range of exposure and processing variables than any standard chemically developed plate. That means more consistent plates with less effort. Even processor cleaning is easy, with minimal levels of maintenance and upkeep required, which also reduces your ecological footprint.

Physical imaging

By using ECO3’s innovative and proven ThermoFuse™ technology, which features purely physical image formation, many exposure variables are eliminated. The coating of Amigo TS is made of millions of individual thermoplastic pearls. It is negative-working, so the 830 nm laser diodes expose the image. In the exposed areas, these thermoplastic pearls are heated, so they melt and fuse, as well as bond firmly to the substrate in order to create the image on the plate. The non-exposed areas on the plate are cleaned out in the processor with a dedicated gum.

| Plate characteristics | |

|---|---|

| Plate type | Negative-working, chemistry-free ThermoFuse™ offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | 830 nm (thermal laser diode) |

| Practical sensitivity | 180 mJ/cm² |

| Platesetter compatiblity | Compatible with most thermal platesetters |

| Image contrast | Good, can be measured with all available densitometers and plate readers |

| Plate sizes | Standard sheet-fed and web sizes |

| Resolution (depending on platesetter) | ABS: 2-98 % at 200 lpi at 2400 dpi |

| Sublima: 1-99% at 240 lpi at 2400 dpi | |

| Gauges | 0.15, 0.20, 0.24, 0.30, 0.40 mm (0.006”, 0.008”, 0.010”, 0.012”, 0.016”) |

| Run length | Up to 200,000 dependent on press conditions, not suited for UV inks |

| Processing | |

|---|---|

| Clean-out gum | Amigo clean-out solution |

| Replenishment rate | 30-50 ml/m² |

| Bath life | 50 m²/l or 6 weeks |

| Processor | Any processor with dip tank, moleton roller preferred |

| Clean-out dwell time | 17 sec in the liquid |

| Environment | |

|---|---|

| Room lighting | Full daylight up to 16 hours |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 70% RH |

| Storage conditions | Ambient temperatures below 25°C, < 70% RH |

| Recommended ECO3 pressroom supplies | |

|---|---|

| Plate cleaner | ANTURA CtP Plate Cleaner |

| Washout gum | ANTURA CleanGum |

| Deletion pen or gel | KP010, KP011 or KP012 |

| Normal short-term storage (max 7 days) | RC795A |

| Baking gum | RC510 |

| Scratch Remover | Reviva Plate |

| Fountain solutions | Amigo TS is compatible with all ECO3 fountain solutions. |

| Roller and blanket washes | Amigo TS is compatible with all ECO3 roller and blanket washes |