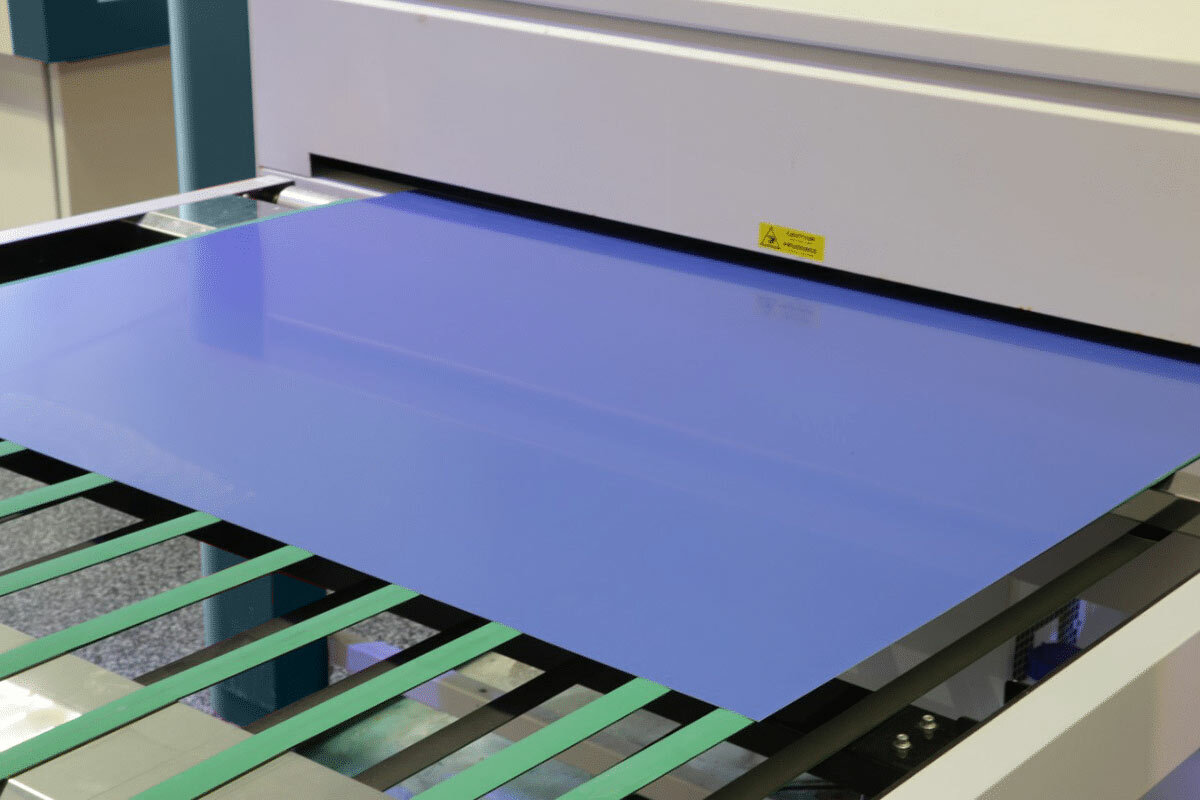

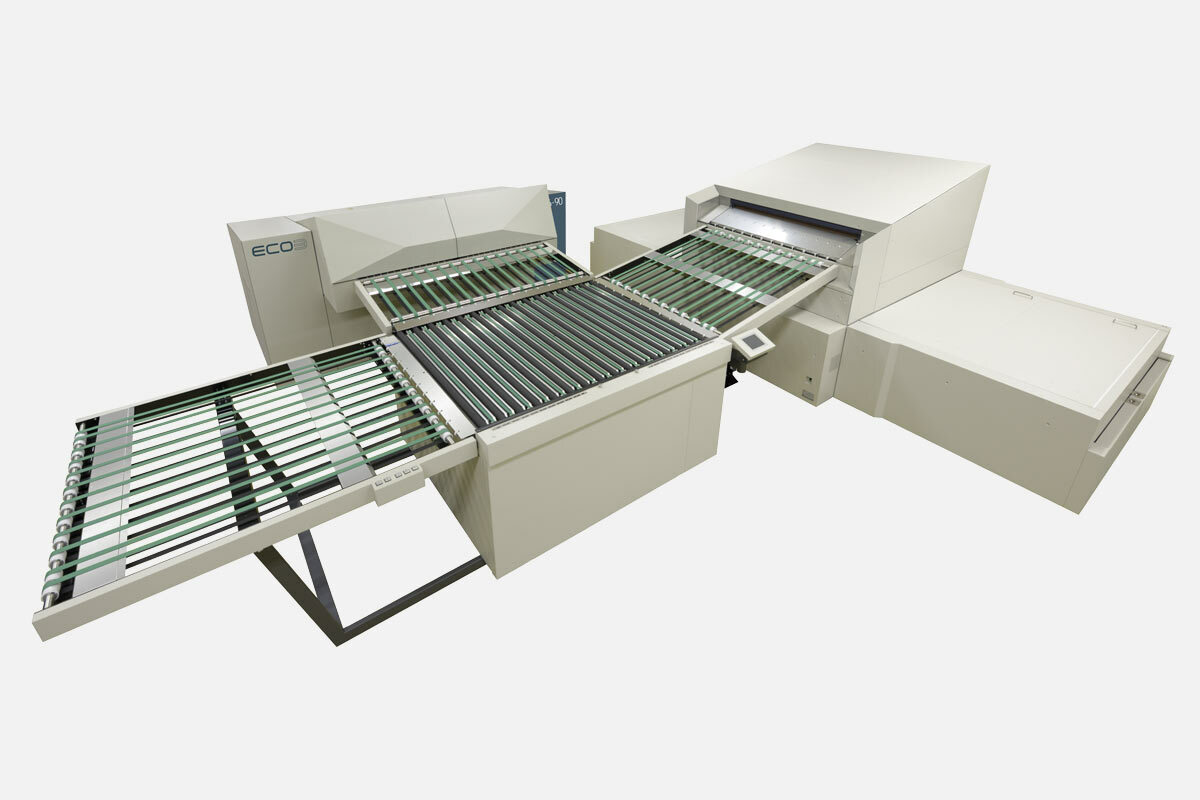

Building on ECO3's philosophy, the Arkana smart processor offers consistent, high-quality plate processing with minimal chemistry usage and maintenance, thus allowing printers to reduce their CO2 footprint further. Maximum throughput on all 8-up and VLF CtP lines makes it the perfect match for high-production and heavy-duty environments.

Arkana features a small developer tank, drastically lowering replenishment rates and considerably reducing chemicals consumption. Thanks to ECO3’s patented gum cascade system in which the gum both cleans the plate and protects it with a finishing layer, Arkana no longer requires water for plate rinsing. All in all, it produces up to 50% less collectible waste compared to other systems on the market. In addition, its long bath life drastically reduces maintenance frequency, while the clean chemistry used in the system reduces maintenance time.

Arkana makes a perfect combination with the Energy Elite Eco printing plate.

Benefits

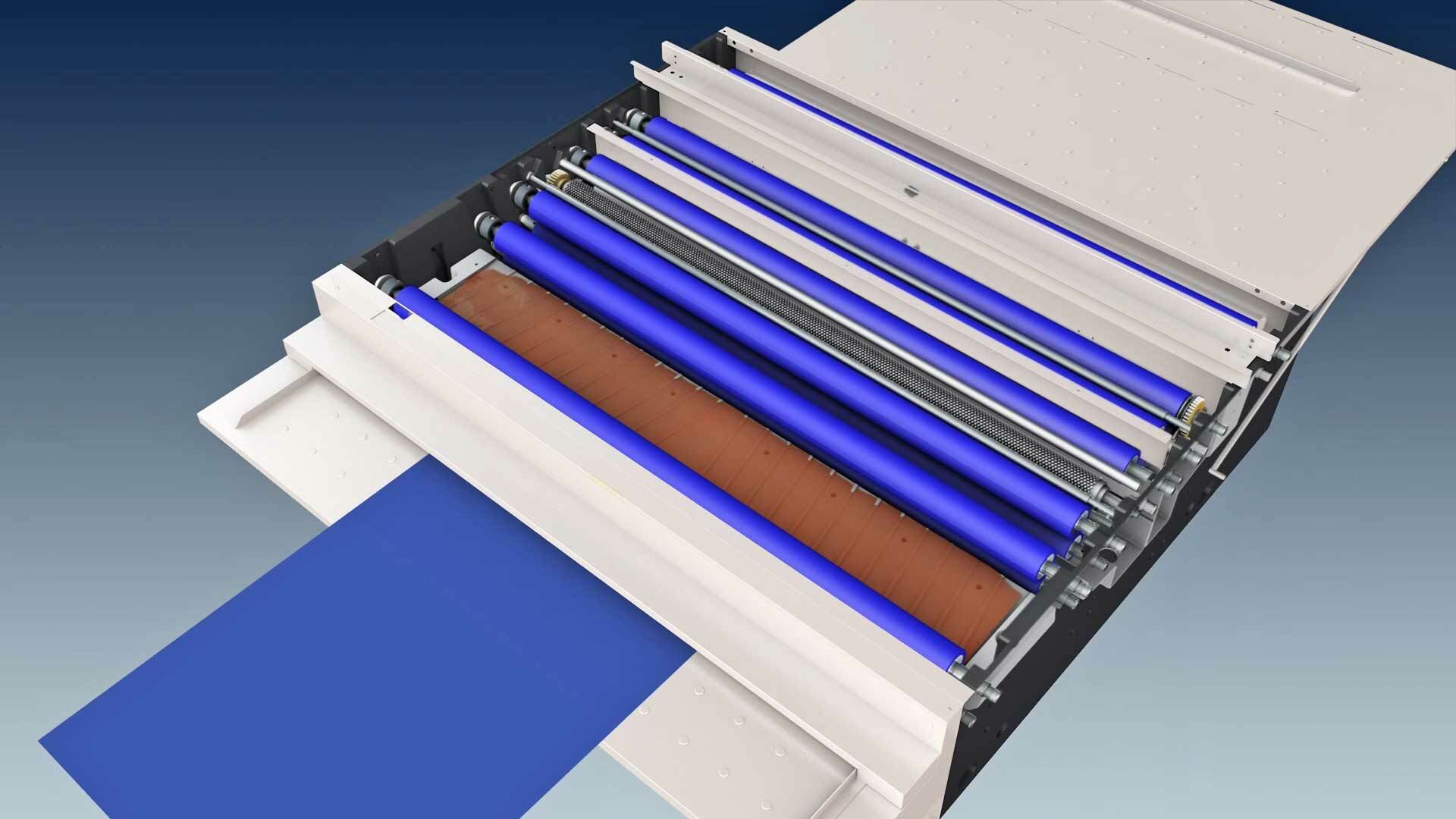

Small-volume developer section

The Arkana smart processing unit is designed with a 10 liter developer tank. In combination with Energy Elite Eco’s clean chemistry this small tank allows for an extended bath life of up to 15,000 m² and extremely low replenishment rates. Total developer consumption is only a fraction (more than 10x less) of that of current systems. A long bath life and a minimum use of chemicals results in a lower cleaning frequency and a drastic reduction of collectable waste.

Cascaded gum sections

As Arkana is using the cascaded gum section for cleaning the plate as well as applying a protective layer, the use of rinse water can be eliminated. This is part of ECO3's aim to reduce the consumption of valuable resources of our planet.

A thin layer of gum is put on the plate to prevent plate oxidation and protect it for handling in the press room. The gum is optimized for optimal protection and only consumes 6ml/m².

Hot air dryer

The plate is dried by hot air, enabling immediate further handling.

| Arkana 85 | Arkana 125 | Arkana 150 | |

|---|---|---|---|

| Plates | Energy Elite Eco | Energy Elite Eco | Energy Elite Eco |

| Plate type | Positive-working, digital thermal offset plate | Positive-working, digital thermal offset plate | Positive-working, digital thermal offset plate |

| Plate width, min.-max. | 200-850 mm (7.9-33.5″) | 200-1250 mm (7.9-49.2″) | 400-1500 mm (7.9-59.1″) |

| Plate length, min. | 300 mm (11.8″) | 300 mm (11.8″) | 300 mm (11.8″) |

| Plate thickness, min.-max. | 0.15-0.40 mm (0.006″-0.015″) | 0.15-0.40 mm (0.006″-0.015″) | 0.15-0.40 mm (0.006″-0.015″) |

| Platesetters | 830nm thermal platesetters | 830nm thermal platesetters | 830nm thermal platesetters |

| Plate speed | 150 cm/min (59”/min) | 150 cm/min (59”/min) | 150 cm/min (59”/min) |

| Plate throughput | 95 plates/h (landscape 745 x 605 mm) | 95 plates/h (landscape 1030 x 790 mm) | 80 plates/h (landscape 1030 x 790 mm) |

| 67 plates/h (portrait 1030 x 790 mm) | 49 plates/h (portrait 1524 x 1143 mm) | ||

| Water for chemistry dilution | Total hardness < 6° dH | Total hardness < 6° dH | Total hardness < 6° dH |

| Temperatures | Developer: min.-max.: 20-28°C (68-82.4°F) | Developer: min.-max.: 20-28°C (68-82.4°F) | Developer: min.-max.: 20-28°C (68-82.4°F) |

| Dryer: min.-max.: 20-70°C (68-158°F) | Dryer: min.-max.: 20-70°C (68-158°F) | Dryer: min.-max.: 20-70°C (68-158°F) | |

| Noise | 70 dB | 70 dB | 70 dB |

| Dimensions (width, length) | 1424 x 1172 mm (56.1″ x 44.2″) | 1824 x 1172 mm (71.7″ x 44.2”) | 2074 x 1172 mm (81.7″ x 44.2″) |

| Electrical specifications Europe | Single-phase: 1W + N + PE – 230V / 15 Amps, 50/60 Hz | Single-phase: 1W + N + PE – 230V / 15 Amps, 50/60 Hz | Single-phase: 1W + N + PE – 230V / 15 Amps, 50/60 Hz |

| Electrical specifications USA | Single-phase: 2W + PE – 208-230V / 15 Amps, 50/60 Hz | Single-phase: 2W + PE 208-230V / 15 Amps, 50/60 Hz | Single-phase: 2W + PE 208-230V / 15 Amps, 50/60 Hz |

| Power | 2.7 kWatt (9213 BTU) | 2.7 kWatt (9213 BTU) | 2.7 kWatt (9213 BTU) |

| Compliancy | CE standards – cTÜV – US certification | CE standards – cTÜV – US certification | CE standards – cTÜV – US certification |

| Accessories | Feed table / Exit table / Drip tray | Feed table / Exit table / Drip tray | Feed table / Exit table / Drip tray |

| Interface for platesetters | Included for all ECO3 platesetters | Included for all ECO3 platesetters | Included for all ECO3 platesetters |

| Optional for third-party platesetters | Optional for third-party platesetters | Optional for third-party platesetters |