Energy Elite Eco is an advanced and remarkably robust no-bake thermal printing plate for high-end, high-performance commercial, packaging and UV printing. It offers an unprecedented run length of up to 600,000* prints (up to 150,000* copies when using UV ink), ensuring maximum productivity especially when combined with our dedicated Elite Eco Founts, for a variety of different applications and press conditions

Even in harsh environments, this robust printing plate does not compromise on its premium, photorealistic imaging quality. Especially designed to be compatible with the latest screening technologies of 340 lpi Sublima and FM10, Energy Elite Eco enables you to create durable images at 1-99% dot resolution, without dot loss.

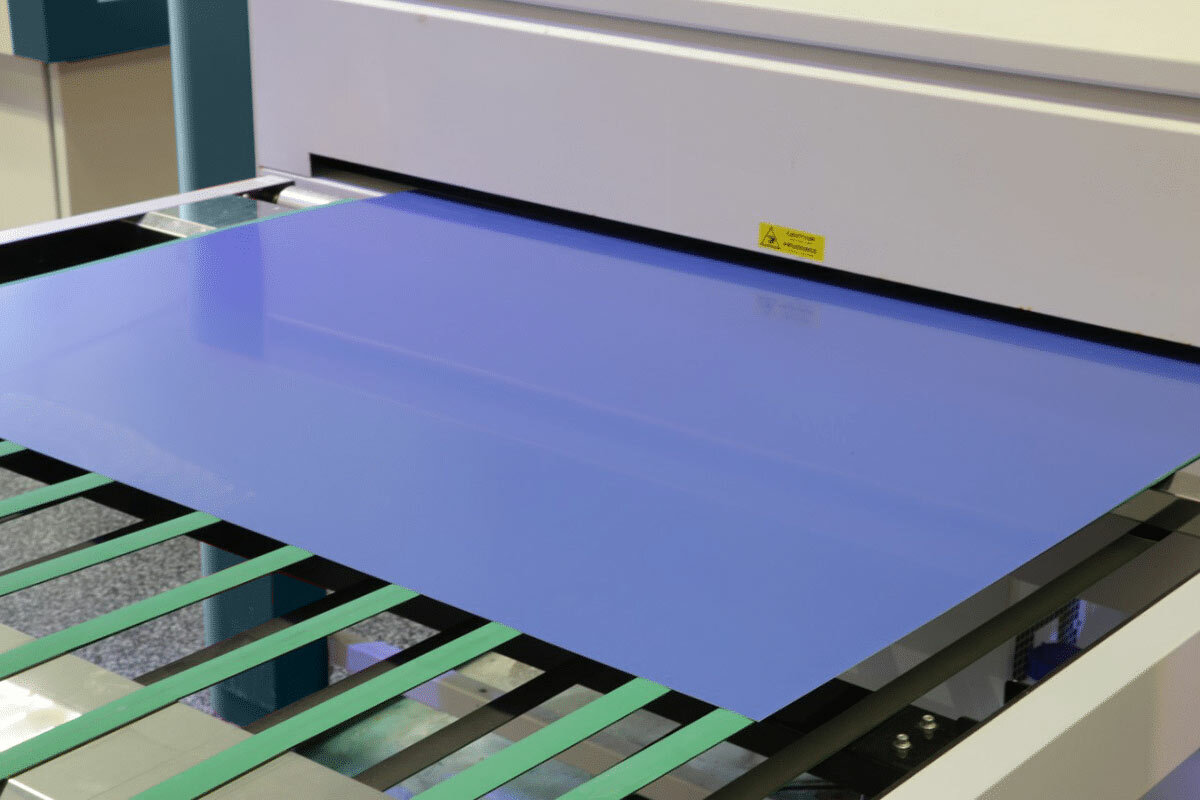

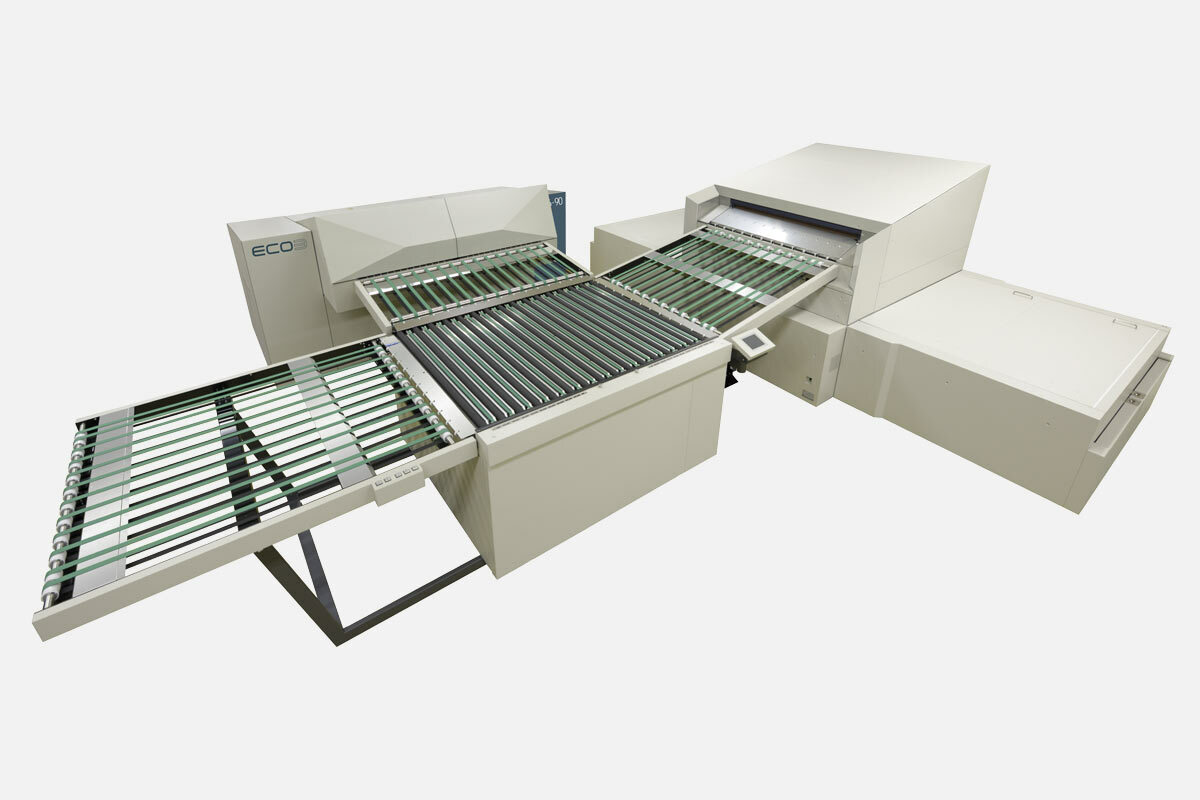

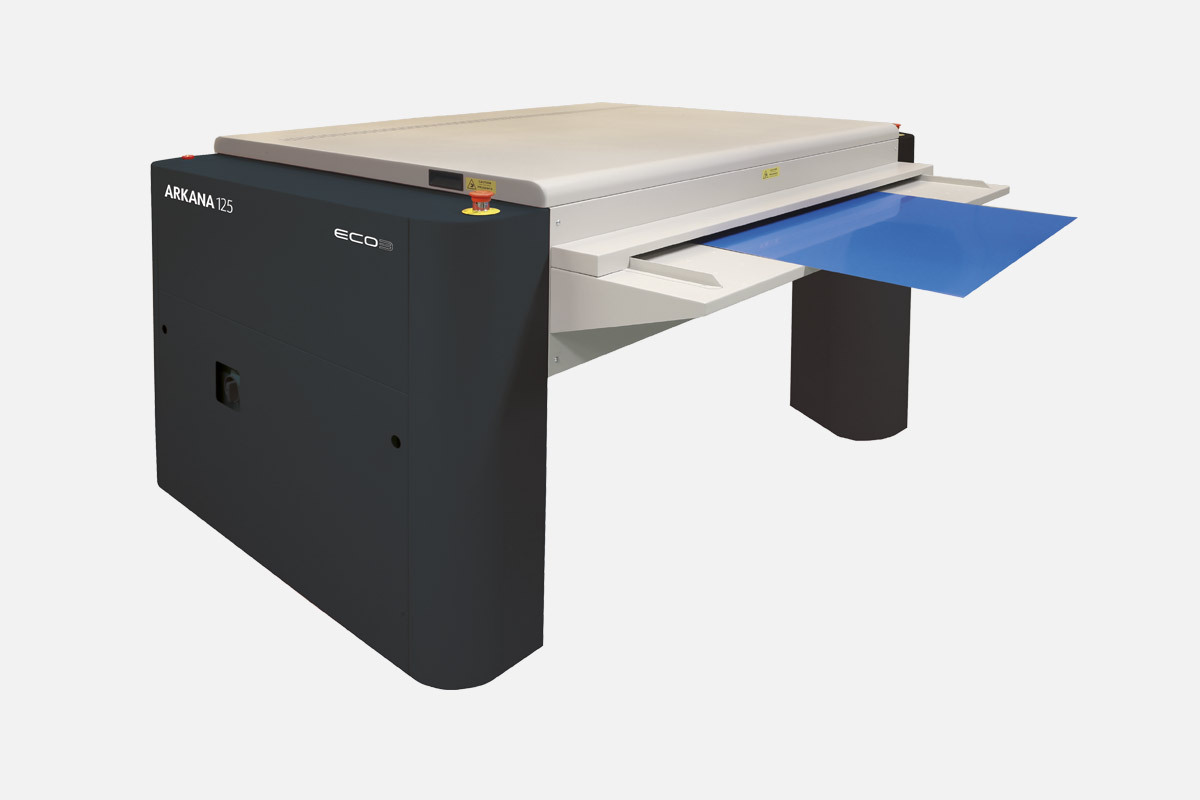

When used in conventional thermal processors, Energy Elite Eco’s clean chemistry allows for significant savings in chemistry consumption and a drastic reduction of maintenance. By combining the Energy Elite Eco plate with the Arkana smart processing technology, the full benefits of its ECO3 features can be achieved: ecology, economy, and extra convenience.

Benefits

ECO3’s advanced coating technology

Thanks to ECO3’s innovative dual-layer coating technology, Energy Elite Eco offers a remarkable robustness that eliminates the need for pre- or post-baking while still achieving runs up to 600,000 prints. It provides high sensitivity for flawless, future-proof performance in all high-speed thermal platesetters.

Furthermore, the advanced Energy Elite Eco technology enables a wide press latitude in sheet-fed, heatset and UV packaging printing. As such, it ensures excellent lithographic performance, fast restarts, low dampening levels, and a stable ink-water balance. Also guaranteeing fast roll-up, Energy Elite Eco enables faster results with less waste.

Supreme, photorealistic imaging quality

As a thermal printing plate, Energy Elite Eco is daylight-safe. Especially designed to be compatible with the latest imaging standards and the highest imaging resolution on the market, the plate enables the creation of durable, photorealistic images with 340 lpi Sublima and FM10 screening technologies. Energy Elite Eco offers quality-consistent printing results at 1-99% dot resolution and without dot loss.

Optimal ECO³ advantages with Arkana

Energy Elite Eco perfectly fits into the ECO3 philosophy, designed with a dedication to ecology, economy, and extra convenience. Combined with standard processors, the printing plate affects a 20% decrease in waste production and chemicals used. It also allows for a longer bath life, less frequent and easier processor maintenance. Processors can be cleaned using standard tap water.

Combine Energy Elite Eco with the Arkana smart plate processing technology to benefit optimally from the full range of its features:

- reduced chemistry consumption, with extremely low replenishment rates

- bath life up to 15,000 m²

- reduced cleaning frequency and easy maintenance due to Energy Elite Eco’s clean chemistry

- no harsh chemicals are required for processor cleaning

- total elimination of rinse water

- total waste reduction of up to 50% compared to conventional processing systems

Optimal performance with Elite Eco Founts

Ink, water, fountain solution, washes… During the printing process, many products interact with your blanket, metal and plate coatings. ECO3 developed the Elite Eco founts alongside the Energy Elite Eco plates to guarantee their optimal performance:

- run length performance is up to twice as high compared to the existing fountain additive in case of chemical plate attack

- good press stability and low water settings

- conomical dosage in combination with most ink types

| Plate characteristics | |

|---|---|

| Plate type | Positive-working, digital thermal offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | 830 nm (thermal laser diode) |

| Practical sensitivity | 90 mJ/cm² |

| Platesetter compatibility | Compatible with 830 nm platesetters |

| Image contrast | Excellent, can be measured with all available densitometers and plate readers |

| Plate sizes | Length: 450-2080 mm |

| Width: 480-1590 mm | |

| Resolution (depending on platesetter) | ABS: 1-99% at 200 lpi at 2400 dpi |

| Sublima: 1-99% at 340 lpi at 2400 dpi | |

| FM 10 µm | |

| Gauges | 0.15 mm, 0.20 mm, 0.24 mm, 0.30 mm and 0.40 mm (0.006″, 0.008″, 0.010″, 0.012″ and 0.015″) |

| Run length (depending on print conditions) | 600,000 (UV inks: 150,000) |

| Processing | Arkana smart processor | Conventional plate processor |

|---|---|---|

| Developer | Arkana developer | THD300 developer |

| Arkana replenisher | THR300 replenisher | |

| Rinse water | Not applicable | Standard |

| Gum | Arkana gum | RC795, RC795-A, Unifin Plus, Antura MAM1 |

| Bath life | 15,000 m² | 15,000 m² |

| Replenishment | 10 ml/m² and 8 ml/h | 40 ml/m² and 40 ml/h (depending on the processor) |

| Environment | |

|---|---|

| Room lighting | Daylight |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 70% RH |

| Storage conditions | Below 32 °C (90 °F), <70% RH |

| ECO3 optimized pressroom supplies | |

|---|---|

| Plate cleaner | ANTURA CtP Plate Cleaner |

| Plate correction | Energy Elite deletion pen + KC 091 |

| Washout gum | ANTURA CleanGum |

| Machine finisher | Unifin Plus |

| Baking gum | RC510 |

| Fountain solution | Energy Elite Eco is compatible with all ECO3 fountain solutions |

| IPA | ANTURA IPA 100 |

| Roller and blanket washes | Energy Elite ECO is compatible with all ECO3 roller & blanket washes |