The Azura TS is a thermal plate for low- to medium-volume commercial printing where simplicity and reliability are priorities. It allows you to preserve the high-quality imaging of traditional platemaking, without press changes or chemical processing.

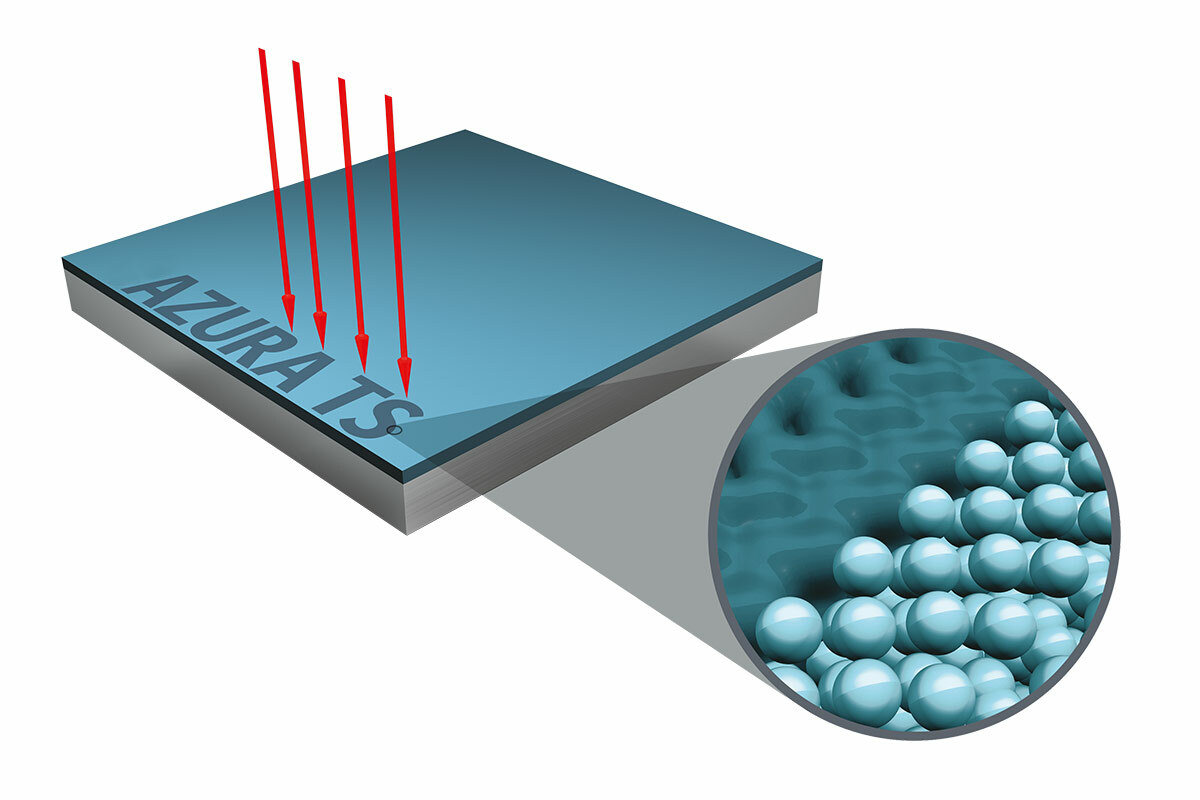

Chemistry-free platemaking? That’s right, thanks to the ThermoFuseTM particles in the anodized aluminum plate coating. The thermal laser heats the coating, causing the particles to fuse and bond firmly to the aluminum. After exposure, the plate is cleaned and gummed in one simple step by the Azura Clean-Out Unit (COU). The result? Razor-sharp image definition in runs of up to 100,000, depending on press conditions.

Benefits

No processing ariables

Azura TS plates can easily be added to any workflow. Because they use no chemical processing, they are safer, simpler and more consistent for everyone to use. And they provide the convenience of daylight handling, allowing them to be used in any prepress environment.

No special press room handling

Azura TS plates work with your existing press workflow, so you can keep on working with the same inks, fountain solutions, or alcohol substrates. The plate prints directly from its electrochemically grained and anodized aluminum substrate, giving you a wider printing latitude.

High-quality results on press

Azura TS plates provide 2 – 98% dpi screen tints at 200 lpi depending on imaging conditions, yielding excellent results on press. They also give you up to 100,000 impressions depending on printing conditions for high productivity.

ThermoFuse technology

During imaging, particles within the Azura TS plate are fused together by the thermal laser to create an image. A physical process then bonds the image to the substrate, with absolutely no chemical processing involved. A dedicated cleaning unit uses gum to finish the plate and clean the un-fused areas, leaving you with a press-ready Azura TS plate.

| Characteristics | |

|---|---|

| Plate type | Negative-working, chemistry-free ThermoFuseTM offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | 830 nm (Thermal laser diode) |

| Practical sensitivity | 200 mJ/cm² |

| Platesetter compatiblity | Accredited for most common external drum thermal platesetters |

| Image contrast | Good. Can be measured with all available densitometers and plate reader |

| Plate sizes | Standard sheet-fed and web sizes |

| Resolution (depending on platesetter) | ABS: 2-98 % at 200 lpi at 2400 dpi |

| Sublima: 1-99% at 240 lpi at 2400 dpi | |

| Gauges | 0.15, 0.20, 0.24 and 0.30 mm (0.006”, 0.008”, 0.010” and 0.012”) |

| Run length | Up to 100,000 dependent on press conditions, not suited for UV inks |

| Processing | |

|---|---|

| Clean-out gum | Azura TS gum |

| Bath life | 300 m²/20 litres |

| Clean-out unit | Azura COU 95, 125, 85, 120 |

| Azura COU CX85, CX125 | |

| Clean-out unit speed | 1.6 m/min in CX85, CX125 |

| Environment | |

|---|---|

| Room lighting | Daylight |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 70% RH |

| Storage conditions | Below 32 °C (90 °F), < 70% RH |

| ECO3 optimized pressroom supplies | |

|---|---|

| Plate cleaner | ANTURA CtP Plate Cleaner |

| Overnight plate cleaner | ANTURA clean gum |

| Deletion pen | KP010, KP011 or KP012 |

| Scratch remover | Reviva plate |

| Fountain solution | Azura TS is compatible with all ECO3 fountain solutions |

| IPA | ANTURA IPA 100 |

| Roller & blanket washes | Azura TS is compatible with almost all ECO3 roller and blanket washes |