Inherent to the nature of a process-free plate, Eclipse eliminates the need for a processor using chemicals. It thus reduces printers’ capex as well as the energy, disposal and maintenance costs in the prepress department, while also gaining them floor space.

Eclipse, however, distinguishes itself from other process-free plates as this drop-in is just as easy to use as a conventional offset plate, combining press purity with excellent and stable image contrast and high scratch resistance. Eclipse is the most convenient process-free plate on the market, eclipsing all others. And it is flexible too, as it can be used with either conventional or H-UV/LED-UV inks.

Benefits

| Plate characteristics | |

|---|---|

| Plate type | Negative-working thermal photopolymer offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | 830 nm (thermal laser diode) |

| Practical sensitivity | 110-130 mJ/cm² |

| Platesetter compatibility | Compatible with 830 nm platesetters |

| Image contrast | Excellent and stable |

| Plate sizes | All common plate sizes |

| Resolution (depending on platesetter) | XM 240lpi @2400 dpi: 1- 99% |

| FM 25 | |

| Gauges | All common plate gauges |

| Run length (depending on print conditions and screen ruling) | Up to 200,000 (UV inks: 50,000) |

| Environment | |

|---|---|

| Room lighting | Standard office light |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 65% RH |

| Storage conditions | Below 32 °C (90 °F), <70% RH |

| ECO3 optimized pressroom supplies | |

|---|---|

| Plate cleaner | Oxidative: ANTURA CtP Plate Cleaner |

| (Low-power curing)-UV: ANTURA UV PL Cleaner | |

| Fountain solution | Eclipse is compatible with all ECO3 fountain solutions |

| Roller and blanket wash | Eclipse is compatible with all ECO3 roller and blanket washes |

| Correction material | Process-free deletion pen |

| Pressroom specialties | ANTURA contrast enhancer |

Eclipse datasheet

No mess in your press

Are you worried about processing on press? With Eclipse, you don’t need to be. Eclipse is based on unique ECO3-developed technology that results in distinctive clean-out behavior. Here is how it works:

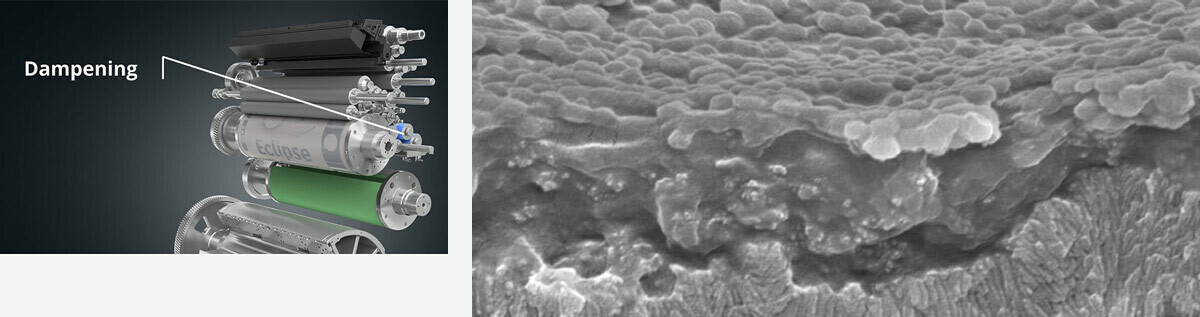

First of all, you need to know that Eclipse consists of:

- a scratch-resistant substrate

- a photolayer

- a protective overcoat

The plate goes through different steps during the printing process:

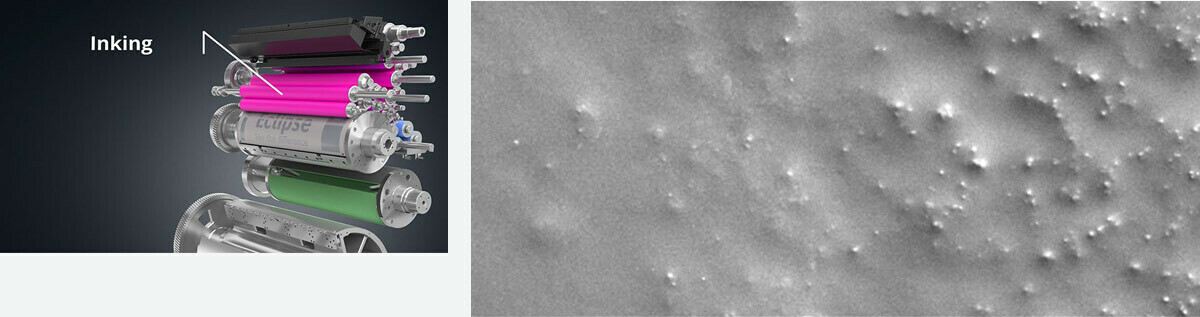

Dampening

The fountain solution makes the overcoat swell.Most of the overcoat and photolayer remain on the plate for now (see edge view image).

Inking

The plate is covered with ink. There is almost no difference between image and non-image parts, which indicates that the coating is still on the plate. It doesn’t dissolve in the fountain solution nor in the ink.

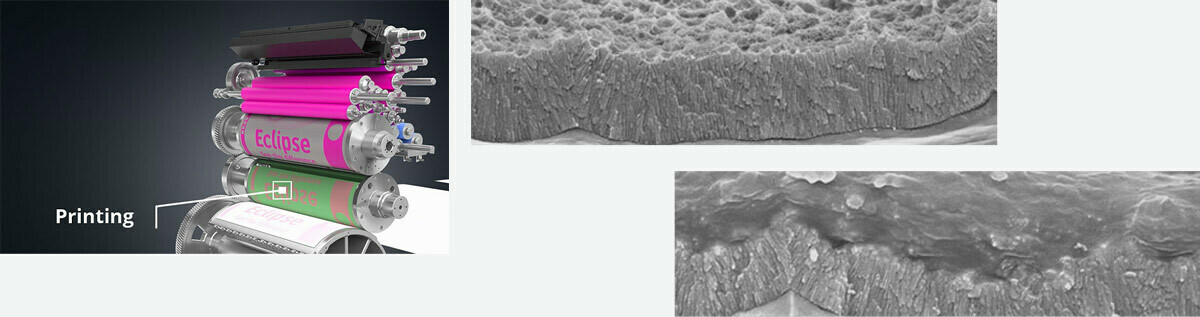

Printing

Only now is the remaining coating removed from the plate. It gets transferred to the blanket, and finally to the paper. The press stays clean!

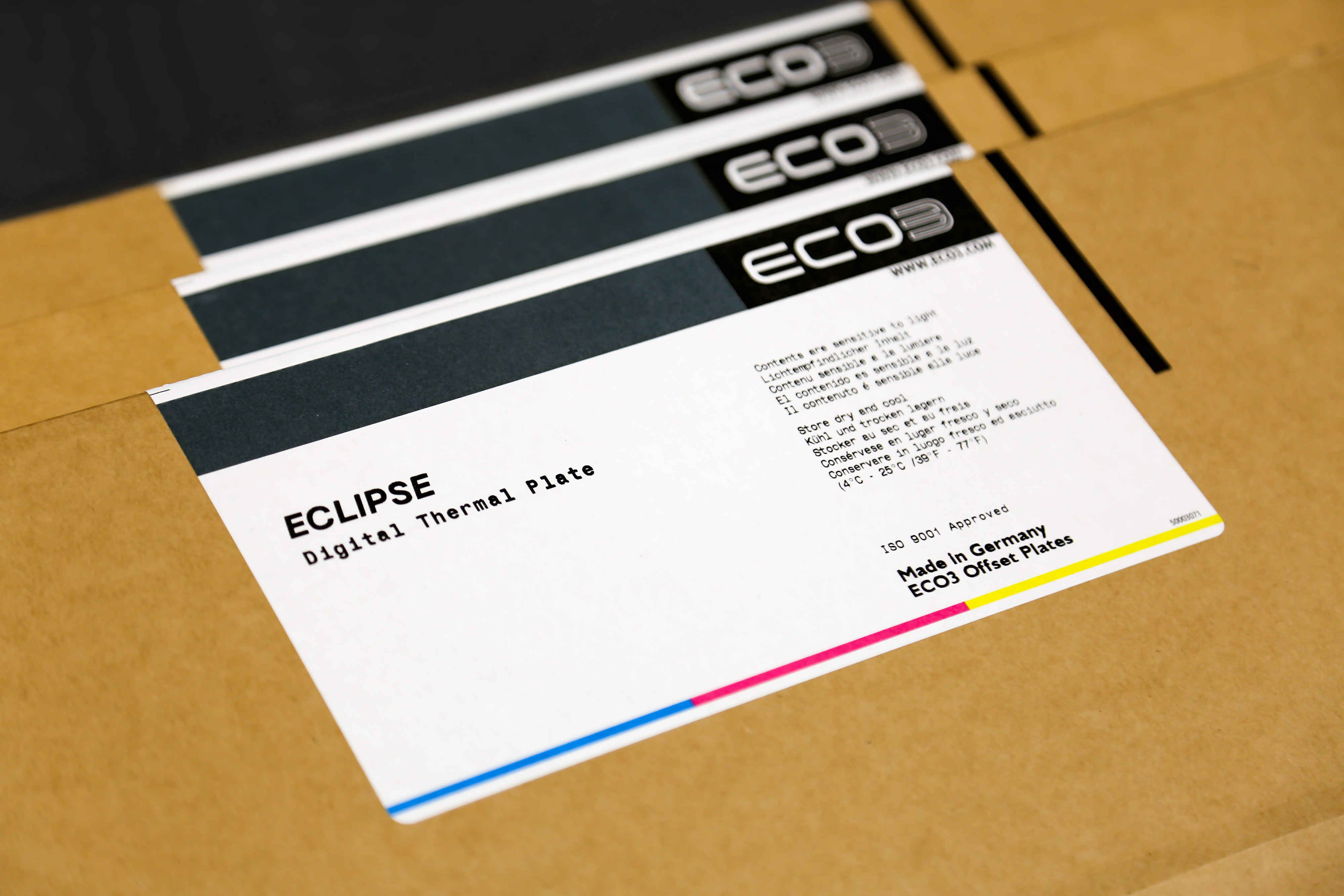

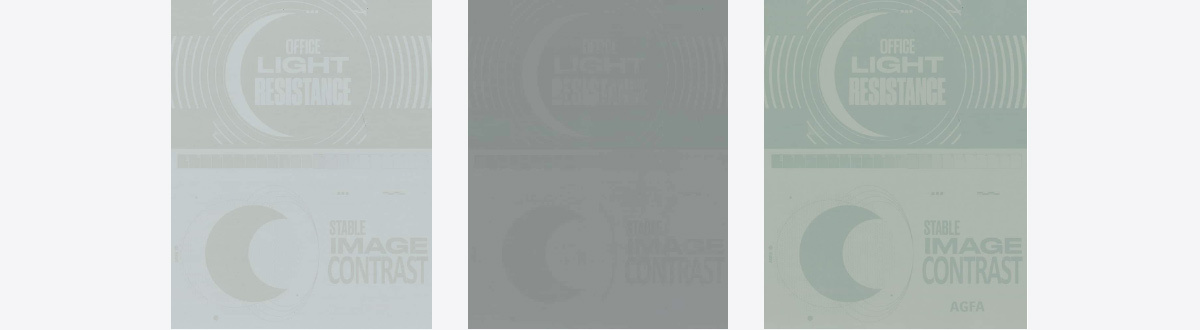

Contrast = convenience = time & cost savings

Eclipse has a superior and stable image contrast, differentiating it from other process-free printing plates. This makes the plate easy to handle:

- Punch & bending units, as well as plate sorting systems, use a printing plate’s contrast to perform a number of automated tasks.

- Great contrast also helps operators to mount the plates correctly on the press.

In addition, Eclipse’s contrast is stable. Commercial printers often prepare printing plates a number of days before printing. While other process-free plates lose their contrast after a mere two hours, Eclipse keeps its great image contrast thanks to ECO3’s unique and irreversible color-forming mechanism. It does so for a week when stored in a dark box, but also after 24 hours in office light! This is particularly convenient as you don’t need to spend time on storing the plates safely.

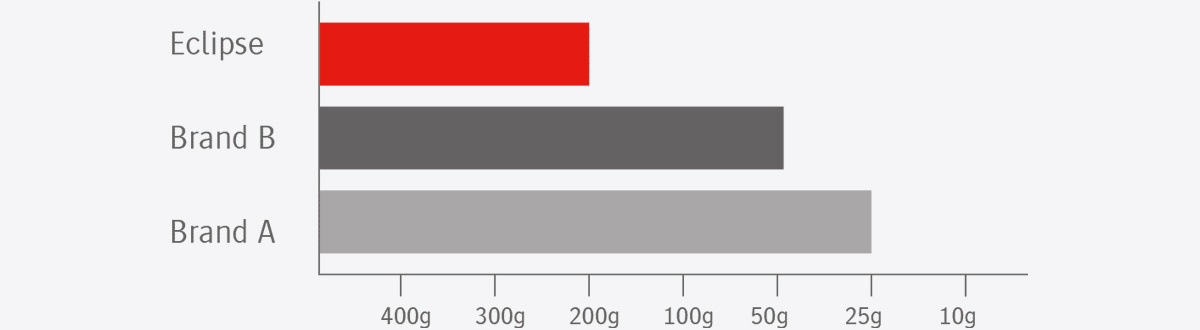

A robust plate

Printing plates get handled all throughout the prepress process. Think of loading them into cassettes or straight into the platesetter, putting them in storage, transporting them from the prepress environment to the pressroom, and of course mounting them on the press.

If a plate is not very robust, it might get damaged, and will need to be remade. That might mean stopping the press and losing time and money. For a commercial printing company with a plate consumption of 20,000 m²/year, costs caused by a scratch-sensitive plate can easily amount to €0.40 per m².

No such issues will occur with Eclipse. This plate is highly resistant to scratches as well as fingerprints. That means you can handle it with confidence.