With Eclipse Pro, the triple synergy of ultra-convenience, excellent and stable contrast and remarkable scratch resistance, translates to a significant reduction in waste – across paper, ink, downtime and labor.

In addition to the elimination of processing equipment and chemicals, Eclipse Pro reduces energy use, and saves time on equipment maintenance and disposal costs. As such, Eclipse Pro actively contributes to a reduction in the environmental impact of print production.

Suitable for the commercial segment, it can be used with either conventional or H-UV/LED-UV inks.

Ultra-convenient process-free plate

No process-free is easier to work with than Eclipse Pro. Not only because of its great contrast and scratch resistance, but also due to its generous print latitude that allows quicker press start-ups and restarts in a broader range of printing conditions. Eclipse Pro requires no major changes to the existing setup; just drop into the existing workflow, making it a very convenient choice for many printing facilities. Convenience is further enhanced by the plate’s ability to print with conventional and H-UV/LED-UV inks, giving printers increased flexibility in daily production.

Up to 24 hours office-light stability

Eclipse Pro retains its great contrast even after 24 hours in office light, making an enormous difference compared to the two hours of other process-free plates. It means you don’t need to store your plates in their box or in otherwise dark conditions – both of which are inconvenient and time-consuming operations. During this period, print quality will be fully preserved in terms of dot gain, toning, start-up time,…

Excellent and stable image contrast

Eclipse Pro offers excellent and stable image contrast for a longer period of time, even when exposed to office light for up to 24 hours (or a week in a dark box), thanks to ECO3’s unique and irreversible color-forming mechanism. The outstanding contrast provides a clear and distinct image, making visual inspection and recognition by punch & bending and barcode systems more efficient, while the image contrast stability saves on the time normally spent putting plates away in storage. The great contrast also helps operators mount plates correctly on the press, thereby avoiding costly mistakes or plate remakes.

Excellent scratch resistance

With a highly robust surface, the plate is better protected through its journey from box to cassette or loader and onto the press, making handling easy and guaranteeing high print quality, every time. Printers experience less costly downtime and plate remakes caused by fine scratches that are most often not detected until the press is running. The result is higher productivity, better quality, and less waste.

| Plate characteristics | |

|---|---|

| Plate type | Negative-working thermal photopolymer offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | 830 nm (thermal laser diode) |

| Practical sensitivity | 100-130 mJ/cm² |

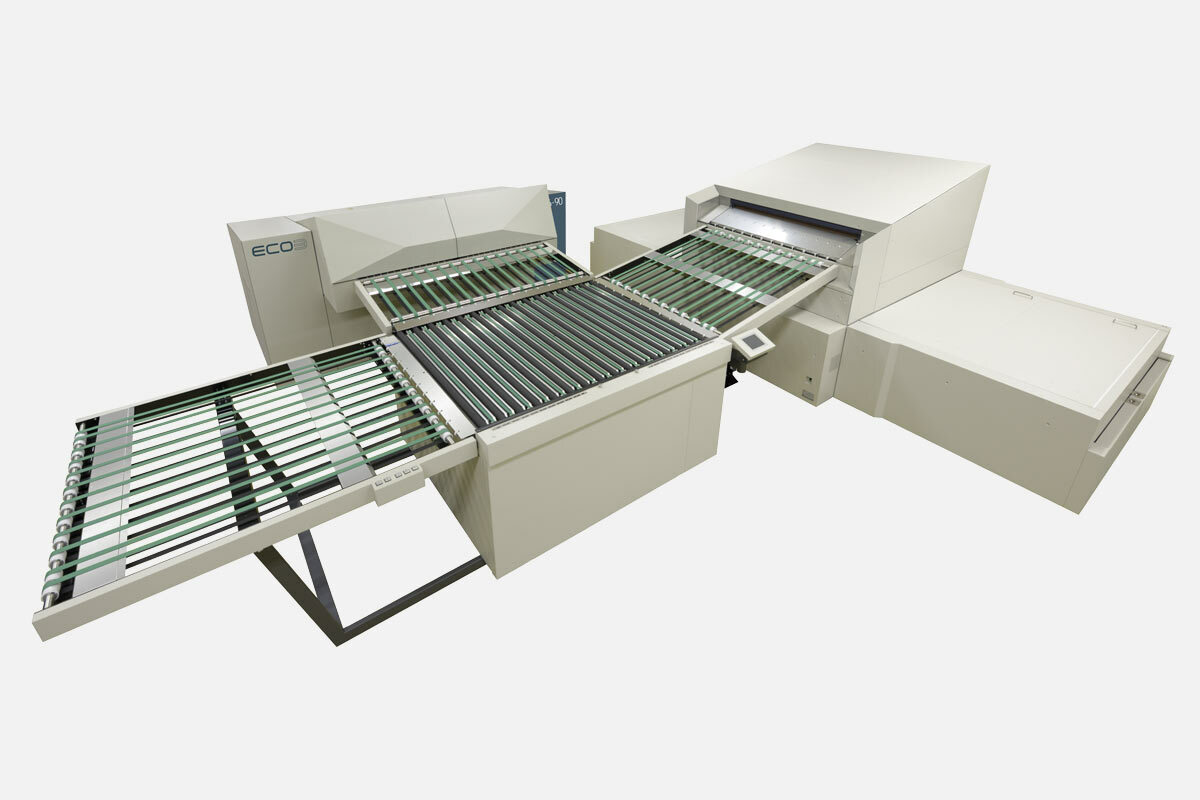

| Platesetter compatibility | Compatible with 830 nm platesetters |

| Image contrast | Excellent and stable |

| Plate sizes | All common plate sizes |

| Resolution (depending on platesetter) | XM 240 lpi at 2,400 dpi: 1- 99% |

| FM 25μ: 1- 99% | |

| Gauges | All common plate gauges |

| Run length (depending on press conditions and screen ruling) | Up to 200,000 (UV inks: 15,000) |

| Environment | |

|---|---|

| Room lighting | Standard office light - 800 lux |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 65% RH |

| Storage conditions | Below 32 °C (90 °F), < 70% RH |

| ECO3 optimized pressroom supplies | Oxidative inks | (Low-power curing)-UV inks |

|---|---|---|

| Plate cleaner | ANTURA CtP Plate Cleaner | ANTURA UV PL Cleaner |

| Fountain solution | ANTURA fount AFS-k | ANTURA fount AFS-k |

| Roller and blanket wash | ANTURA Wash 40/60 QD Wash | ANTURA UV Wash |

| Pressroom specialties | ANTURA Contrast Enhancer | ANTURA Contrast Enhancer |