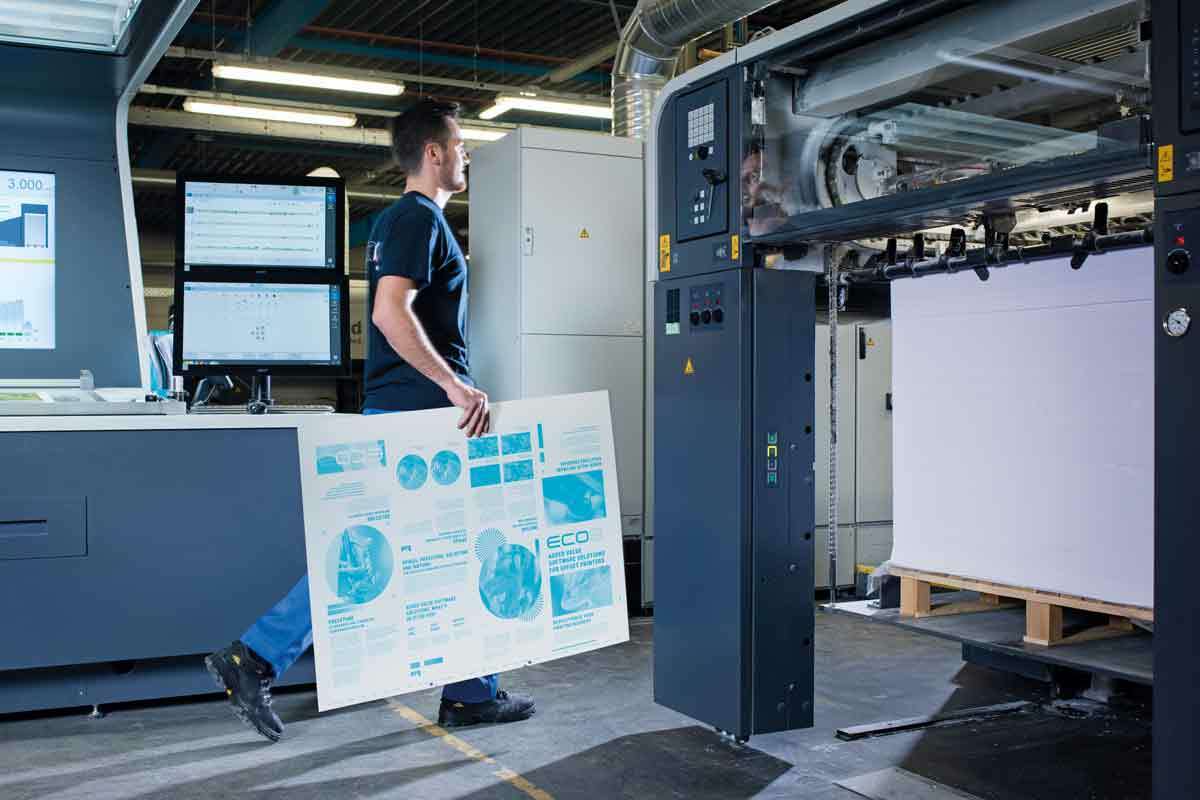

The Avalon C4-30 thermal computer-to-plate system is a compact yet powerful solution for commercial and packaging printers, combining automation with high-quality imaging. It handles plates up to 925 x 675 mm, with a throughput of up to 21 or 29 plates per hour.

Designed for efficiency and profitability, the Avalon C4-30 ensures seamless operation and top-tier image quality. Optional features include an inline punching system and flexible loading options—cassette, single, or multi-cassette loader—for maximum automation and convenience.

ECO3 offers the Avalon C4-30 as part of a complete system solution, including offset plates, Apogee or Amfortis workflow software, and support contracts.

Benefits

Exceptional print quality and speed

The Avalon C4-30 utilizes multi-channel fiber-coupled thermal laser-diode technology, providing precise dot reproduction on the plate for print quality up to 240 lpi Sublima screening. With 32 or 48 channels, the Avalon C4-30 delivers a maximum plate output of up to 21 or 29 plates per hour.

Process automation options

Enhance efficiency with a range of automated loading options:

- Integrated cassette – holds up to 50 plates

- Single autoloader – available with 200 or 500 plate capacity

- Multi-autoloader – features 3 cassettes, each holding 50 plates

For seamless workflow integration, activate the inline press punch before loading the plate onto the external drum. After imaging, plates are automatically transferred to an online processor or clean-out unit.

Additionally, the L-bridge offers flexible plate routing in three different directions, with the option to integrate punching sets.

Flexible workflow

Empower your operators with flexibility. Load a plate while imaging another, leaving the unit unattended. As the first plate exits the external drum, the second plate automatically enters the system – all without requiring operator intervention.

| Avalon C4-30 E & S | |

|---|---|

| Imaging technology | - Avalon C4-30 E: 32-channel laser diodes - Avalon C4-30 S: 48-channel laser diodes |

| Laser type | 830 nm thermal |

| Recording system | External drum |

| Press punch | Max. 3 units |

| Resolutions | 1200/2400/2540/2800 dpi |

| Throughput (925 x 675 mm, 2400 dpi) | - Avalon C4-30 E: 21 plates per hour - Avalon C4-30 S: 29 plates per hour |

| Plate loading & unloading configuration | |

|---|---|

| Manual loading/unloading | Yes |

| Loading options | - Integrated ALS - Avalon C4 ALS - Avalon C4 ALS 500 - Avalon C4 ALM3 |

| Plate characteristics | |

|---|---|

| Min. plate size (along drum x around drum) | 240 × 240 mm (9.45 × 9.45”) |

| Max. plate size (along drum x around drum) | 925 × 675 mm (36.42 × 26.57”) |

| Thickness | 0.15 - 0.30 mm (6 - 12 mil) |

| Max. exposure size (along drum x around drum) | 925 × 663 mm (36.42 × 26.1”) |

| Autoloaders | |

|---|---|

| Plate capacity (0.3 gauge) | - Integrated ALS: 50 plates - Avalon C4 ALS: 200 plates - Avalon C4 ALS 500: 500 plates - Avalon C4 ALM3: 3 x 50 plates |

| Number of cassettes | - Integrated ALS: 1 cassette - Avalon C4 ALS: 1 cassette - Avalon C4 ALS 500: 1 cassette - Avalon C4 ALM3: 3 cassettes |

| Weight | - Avalon C4 ALS/ ALS500: 560 kg (1,234.6 lb) - Avalon C4 ALM3: 600 kg (1,322.8 lb) |

| Size (W x D x H) | - Avalon C4 ALS/ ALS500: 1,600 × 1,100 × 1,100 mm (63.00 × 43.31 × 43.31”) - Avalon C4 ALM3: 1,600 × 1,200 × 1,100 mm (63.00 × 47.24 × 43.31”) |

| Technical data | |

|---|---|

| Weight | Standalone: 1,080 kg (2,381.0 lb) |

| Size (W x D x H) | Standalone: 1,650 × 1,990* × 1,070 mm (64.96 × 78.35* × 42.13") (*including loading and output table) |

| Temperature range | Recommended: 21-25 °C |

| Humidity range | 40-60 % RH (no condensation) |

| Power | Single-phase 200-240 V, 50/60 Hz |