Can cost savings be achieved while preserving or even increasing the quality of prints? InkTune proves that it’s possible. As its name implies, InkTune helps you save on ink costs. It uses Grey Component Replacement (GCR), which substitutes expensive CMY inks with the more economical black (K) ink. But it also does a lot more: it improves color stability on the press, as well as image quality and consistency. As a result, there is less interference between different inks, the inks dry faster and printing speeds can be higher.

InkTune is a unique solution because it is entirely integrated into the prepress workflow. The software works its magic during the rendering process without requiring extra hardware or user expertise. This makes InkTune a cost-effective solution that improves quality and lowers environmental impact.

Benefits

Higher quality printing

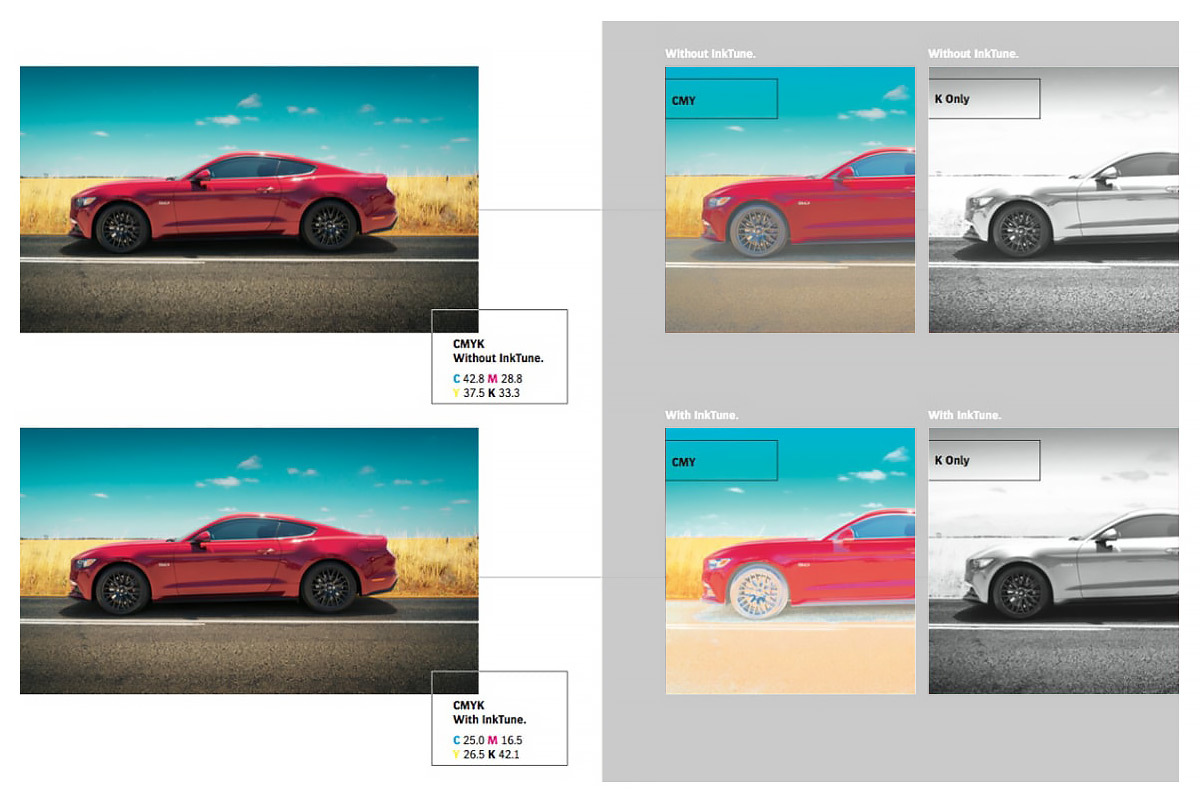

Because there is less information in the color separations, registration errors and rosette structures are less visible, so images appear sharper. Every color transformation is calculated by ECO3's patented Advanced CMM (Color Management Module), which uses industry standard or customer ICC profiles. No color deviations are visible when the original color separations of images and text are compared to the InkTuned result.

Increased consistency and stability

InkTune avoids color casts through variations in ink weight on press by producing more consistent greys. Images printed with the use of InkTune technology are consistent throughout the press run, with stable color reproduction under all lighting conditions. In short, InkTune drives superb color consistency as well as improved stability of printing on press.

Improved productivity

InkTune contributes to printing productivity by:

- shortening press set-up time required to stabilize color tones and neutral grey balance;

- applying less ink onto the paper, improving ink setting and shortening drying times. As a result, less drying powder is needed, and post-press activities can start sooner.

Lower costs

With InkTune, the total ink coverage used is reduced, and black ink now replaces a proportion of the expensive colored inks previously used. Both factors contribute to substantial cost savings. In commercial print applications, we have measured savings of between 10% and 30%.

Less anti-offset powder needed

Using less spray powder is environmentally friendly and can lead to a more vibrant and glossy appearance, enhancing the overall print quality and visual appeal of the final product.

PressTune and InkTune: a printing power combo

Use InkTune with PressTune, ECO3’s smart print management solution, for optimum results. With its powerful process control and analytics capabilities, PressTune helps create the ideal environment for InkTune to work its magic. In addition, the cloud-based PressTune solution allows you to deploy InkTune across different printing sites, greatly enhancing opportunities for cost reduction and promoting consistency across the board. Your clients will love it.