Investing in a new press often promises increased productivity—but it can also introduce unexpected challenges. That was the case for TOWA Corporation, a leading Japanese printing company, when they installed a Koenig & Bauer Rapida 106X in December 2023.

This seven-color LED-UV press, equipped with a varnish coater and capable of printing up to 20,000 sheets per hour, was selected to boost output and profitability when printing on microflute corrugated board. That transition to high-speed short-run cardboard jobs required careful product and process optimization.

Building on innovation and value-added printing

Founded in 1983 in Osaka, Japan, TOWA has built a reputation for innovation in commercial printing. Over the past decade, the company has shifted its focus toward high-value applications, particularly in the cardboard segment. This includes printing store fixtures, structures or displays used in retail to present products, such as shelves, display stands, racks, or promotional units, manufactured from thin corrugated board.

TOWA not only handles the printing but also integrates post-processing and in-house assembly. This vertical integration has allowed the company to maintain strong profit margins despite the challenges of short-run production.

With demand for traditional commercial printing in decline and the limited efficiency of its legacy equipment , TOWA saw an opportunity to invest in technologies to drive the growth of its expanding cardboard business. The Rapida 106X was chosen for its speed, automation and ability to handle a wide range of substrates—from thin paper to microflute corrugated board up to 1.2 mm thick.

The challenges of short-run high-speed cardboard printing

While the Rapida 106X offered impressive specifications, its integration into TOWA’s workflow was far from plug-and-play. The company’s average print run is under 2,000 sheets, with 250 to 300 jobs processed monthly. This means frequent job changes, minimal setup time and very little room for error, especially when working with expensive cardboard stock that is often supplied with no surplus.

One of the key challenges was ink control during press startup. In high-speed UV printing, particularly on substrates such as microflute corrugated board, the ink-water balance must be tightly controlled. Insufficient control leads to excessive substrate waste and ink consumption—two costly issues in short-run environments.

Furthermore, sustaining print stability at speeds of up to 20,000 sheets per hour, especially when working with UV inks and automatic color control systems, proved to be a highly complex task.

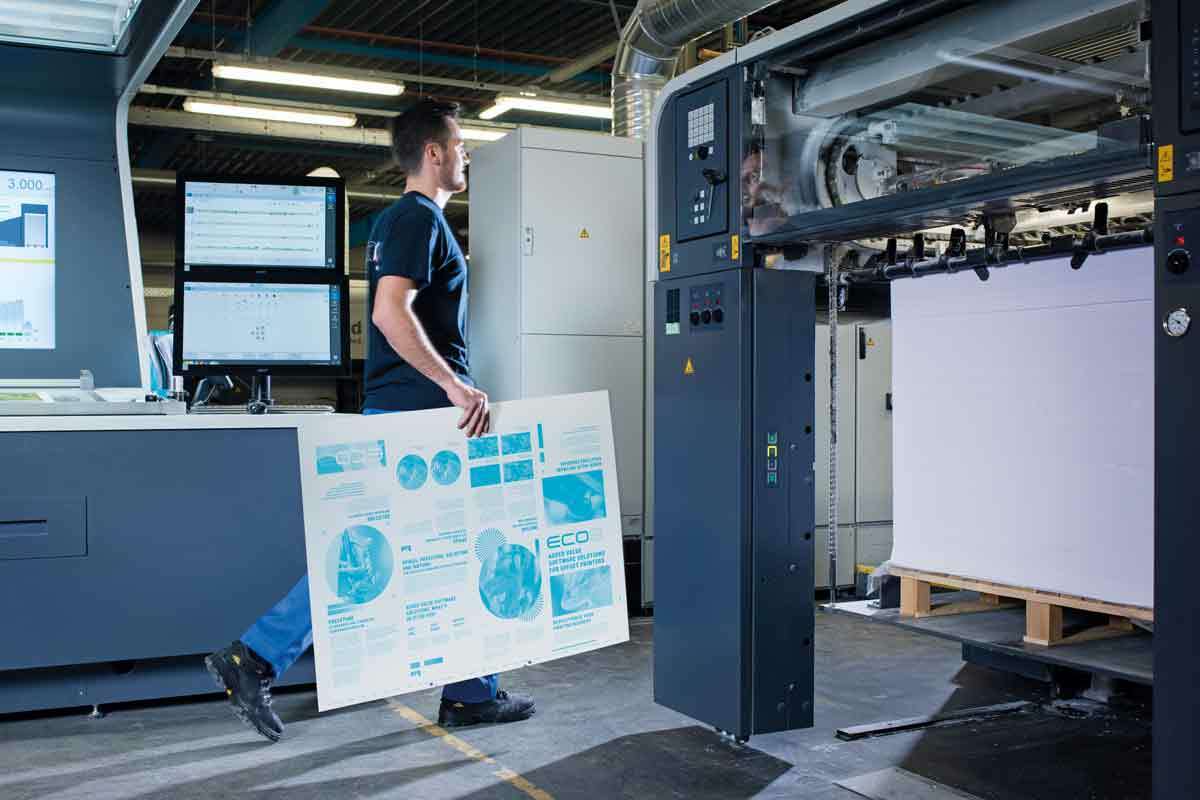

Choosing Adamas, the plate that matches the process

To address these challenges, TOWA turned to ECO3’s Adamas plates. Adamas is a chem-free offset plate designed for high-performance environments. It combines excellent image quality and strong durability—up to 75,000 impressions on UV presses.

For TOWA, Adamas proved to be the ideal match for their demanding setup.

“It’s not about which plate technology is best, it’s about what fits your setup,” explains Mr. Yoshiro Takamoto, President of TOWA. “For our short-run, thick paper jobs at high speed with UV inks, Adamas chem-free plates proved to be the most suitable.”

The results were immediate and measurable. Ink consumption dropped significantly, and paper waste was reduced to just one-quarter of previous levels. “Even the person in charge at the paper recycling company was surprised,” says Takamoto. The company now prints up to 120,000 sheets per plate without replacement, far exceeding the rated durability.

Fine-tuning the process

Once Adamas was adopted, TOWA began readjusting other consumables used in their process, particularly the fountain solution and inks. In collaboration with a chemical firm, they developed H Liquid, a dedicated fountain solution designed to comply with Japanese regulations restricting the use of alcohol in printing. Together with highly fluid UV inks optimized for high-speed operation and Adamas plates, this combination created a stable and efficient printing environment that minimizes waste while maximizing throughput.

Adamas: a pro-grade plate for demanding workflows

For TOWA, the adoption of Adamas has been transformative. The company consumes around 1,000 plates per month, which are imaged using an Avalon N8-80XT platesetter and Adamas COU125 clean-out unit.

Even with rising consumable costs, the gains in productivity and waste reduction have delivered substantial cost savings.

“I think Adamas is a ‘special plate’, in a sense,” says President Takamoto. “When combined with the right printing know-how, it delivers outstanding results and benefits.”

Abbreviated article, originally published in Printing Journal (June 2025)

TOWA website

Adamas

A robust pre-heat-free, chem-free printing plate with outstanding performance for demanding commercial, packaging and newspaper printing applications.

Discover