Located in Marienfelde, on the southern outskirts of Berlin, PIEREG Druckcenter was founded by Erhard Pietsch and Sven Regen. It began operating at the very start of 2004 and is today one of the city’s most productive print shops. Working in three shifts around the clock, the company offers a full print service from initial consultation and advice through prepress, printing and finishing to final assembly and shipping.

Throughout its prepress operation and pressroom, PIEREG relies on ECO3 innovation to respond efficiently to customer demands for high quality, punctuality, and above all, sustainability.

The decision in favor of the ECO3 product range was quite simple. We wanted to have a single supplier and contact for ordering goods and dealing with support and service issues.

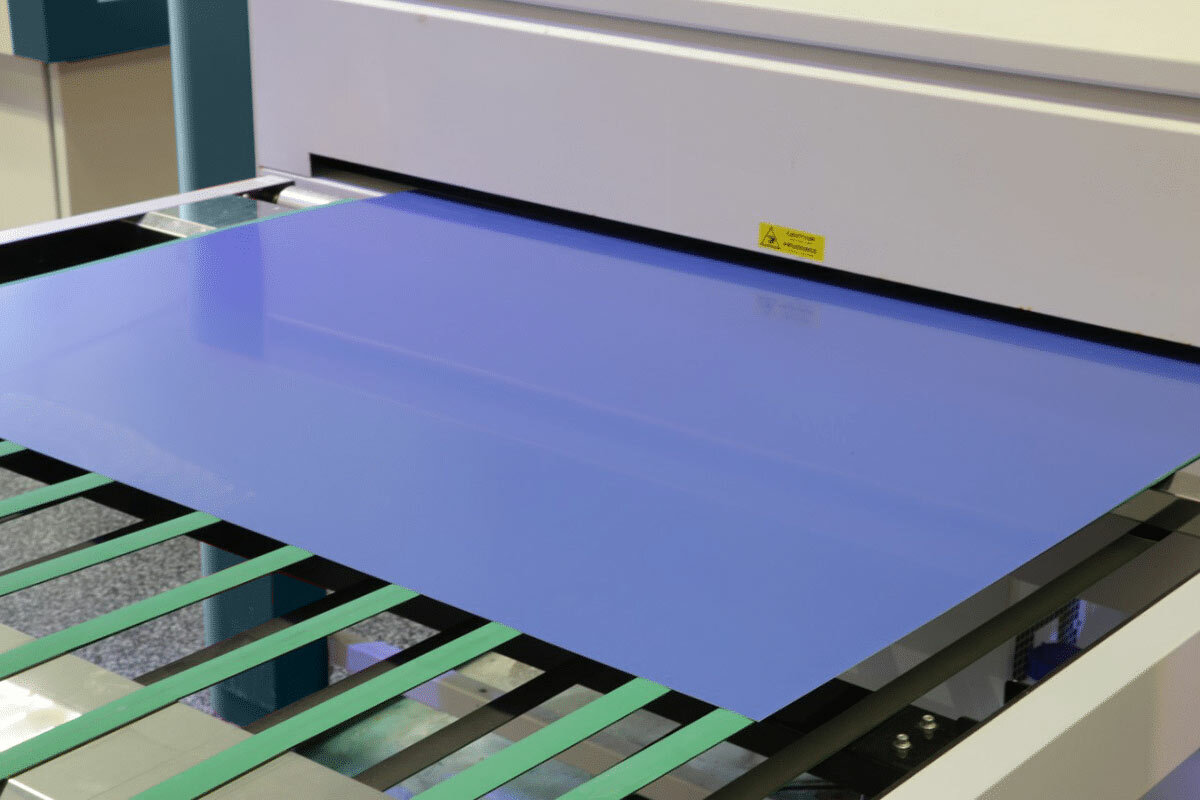

Right from the start, the company implemented the entire Apogee workflow, which now also includes InkTune and PressTune for optimizing ink use and print consistency. PIEREG also employs Sublima screening technology and is in the process of integrating WebApproval. An Avalon N8–90 XT platesetter with automatic plate loader and an Arkana 125 processor deliver press-ready Energy Elite Pro printing plates for the company’s three offset machines.

The printing presses, two of which are B3 sized, benefit greatly from the advantages of the ECO3 Energy Elite Eco plates. PIEREG prints on coated papers using 280 line Sublima screening, and the robustness and scratch-resistance of this plate type allow for 260,000 to 300,000 copies to be printed with a single set of plates. Meanwhile the Arkana system offers a longer bath life and reduced water consumption, as well as the opportunity to reduce the use of chemicals and large stocks.

Focus on sustainability

Sustainability is a crucial factor in the choice of ECO3 as supplier partner, enabling the company to reduce waste of materials, time and energy. PIEREG was proud to receive Blue Angel certification from the German Federal Government in 2023 in recognition of its dedication to the protection of the environment and social responsibility. Other initiatives include solar panels that produce up to 40% of the daily electricity demand, investment in modern machinery, and LED lighting in the production halls.

The biggest advantages of the ECO3 product range in relation to our sustainability policy can be found in the high level of reliability, the fast production times, and the guarantee that there won’t be any mistakes made in the workflow.

Sebastian Preissler, Operations Manager – PIEREG Druckcenter Berlin

After two decades in business, the team at PIEREG are clear about their choices and fully transparent about how the collaboration with ECO3 has contributed to the company’s success.

“Our years of cooperation speak for themselves. We enjoy working with ECO3 and open our doors to anyone who wants to take a look at our operation.”

Sven Regen, Managing Director – PIEREG Druckcenter Berlin

Energy Elite Eco

Ready for the next generation of no-bake, long-run thermal printing plates? Energy Elite Eco has it all: an even higher run length, durability and photorealistic imaging quality.

Discover

Apogee

Innovate, interact, and optimize. That’s the Apogee workflow software philosophy with which you stay ahead of the competition. Because quality and efficiency can never be rated too high in the printing business.

Discover

Sublima

The highest quality of print begins with the right screening solution: Sublima, the perfect cocktail of two proven screening technologies.

Discover