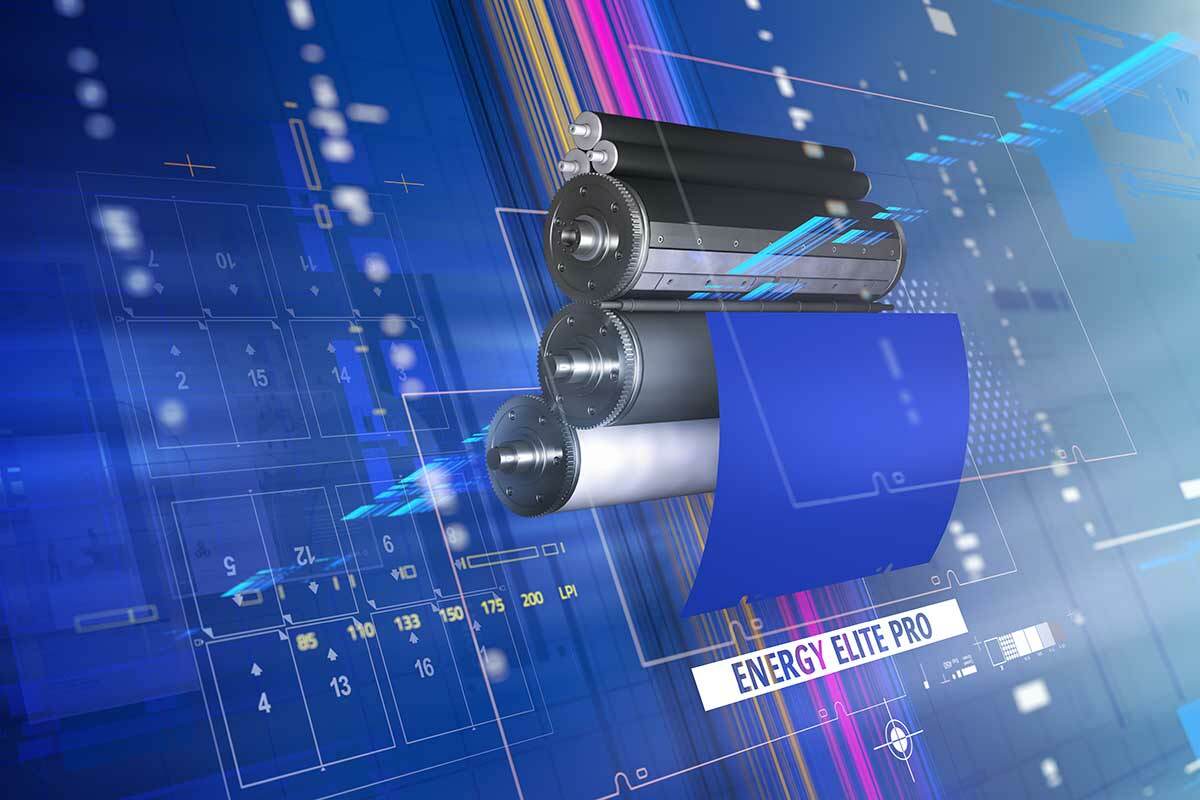

Energy Elite Pro is the next-generation no-bake thermal plate. It offers consistent printing quality, high productivity and lower chemistry consumption. And it combines all that with run lengths up to 400,000 copies – in aggressive environments (e.g. UV and metallic inks) up to 150,000 copies. For even longer runs, Energy Elite Pro can be baked.

Its chemical resistance makes the use of fountain solutions for alcohol-free and reduced-alcohol printing easy, even without baking. Its unique developer and replenisher, specifically designed for Energy Elite Pro, additionally ensure longer bath life and easy cleaning. Raise productivity while reducing your ecological footprint.

Benefits

No-bake Technology

The double-layer coating technology gives Energy Elite Pro its robust properties. The second layer ensures high chemical resistance. Therefore Energy Elite Pro performs flawlessly in high-speed platesetters and is compatible with UV and metallic inks, even without baking.

Energy Elite can achieve runs up to 400,000 and in harsh environments (e.g. UV and metallic inks) up to 150,000 impressions without baking (depending on the platesetter).

Durable High-Quality Imaging

Energy Elite Pro is office light-safe. This positive thermal plate provides durable, high-quality imaging. The innovative double-layer technology delivers 1 to 99% dot resolution at 200 lpi.

Exceptional Print Quality

With CristalRaster III stochastic screening, Sublima screening or the revolutionary new SPIR@L screening, Energy Elite Pro always delivers exceptional quality. The new double-coating formula ensures a sharp dot throughout the run.

More economical

Up to 20% faster than Energy Elite plates, and up to 20% lower chemistry use

Operator-friendly

Fully operational in office light

| Plate characteristics | |

|---|---|

| Plate type | Positive-working, thermal offset plate |

| Substrate | High-quality grained and anodized aluminum |

| Spectral sensitivity | 830 nm (thermal laser diode) |

| Practical sensitivity | 100 mJ/cm² |

| Platesetter compatiblity | Compatible with all 830 nm platesetters |

| Image contrast | Excellent, can be measured with all available densitometers and plate readers |

| Plate sizes | Length: 450-2080 mm |

| Width: 480-1590 mm | |

| Resolution (depending on platesetter) | ABS: 1-99% at 200 lpi at 2400 dpi |

| Sublima: 1-99% at 340 lpi at 2400 dpi | |

| FM 20 µm | |

| Gauges | 0.15 mm, 0.20 mm, 0.24 mm, 0.30 mm, 0.35 mm, and 0.40 mm (0.006″, 0.008″, 0.010″, 0.012″, 0.014″ and 0.016″) |

| Run length | 400,000 (UV inks: 150.000) |

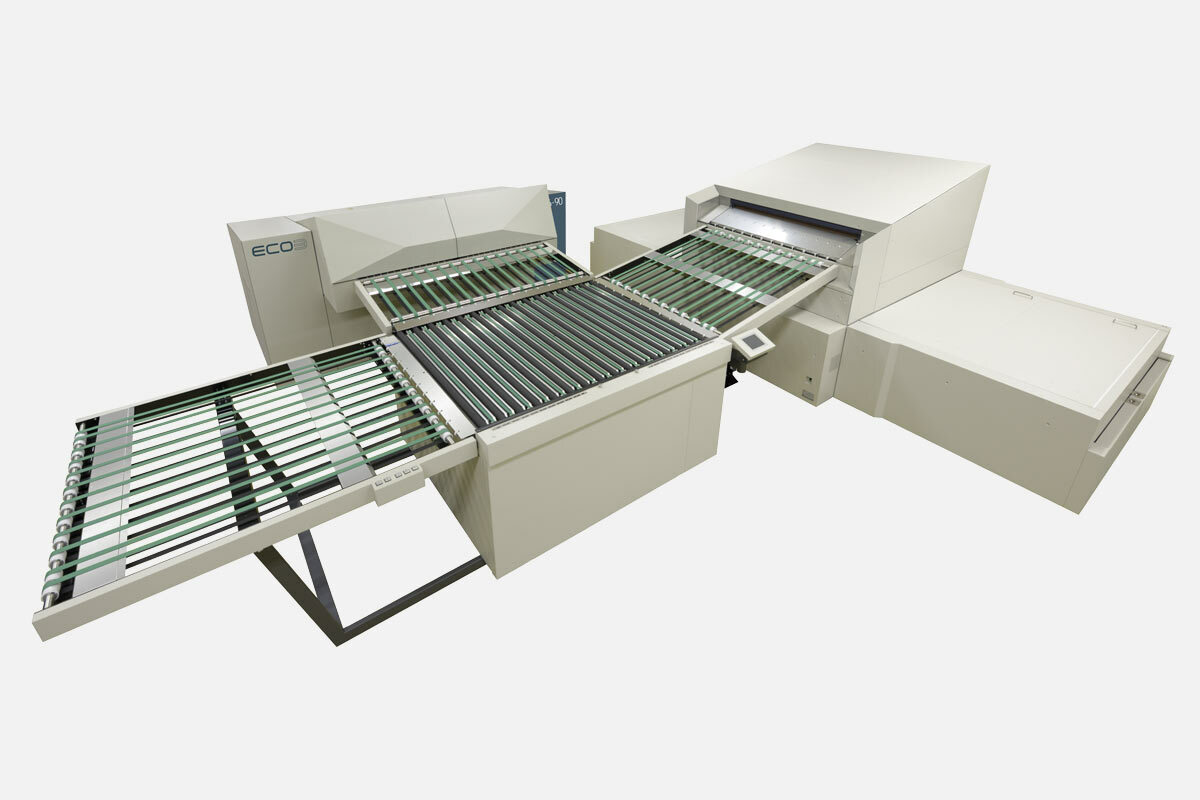

| Processing | |

|---|---|

| Developer | THD200 developer (THR200 replenishment) |

| Replenishment rate | 50-70 ml/m² and 50-80 ml/h |

| Bath life | 5000 m² |

| Processor | All thermal plate processors |

| Environment | |

|---|---|

| Room lighting | Daylight |

| Room conditions (T, RH) | 18-24 °C (64-75 °F), < 70% RH |

| Storage conditions | Below 32 °C (90 °F), <70% RH |

| ECO3 optimized pressroom supplies | |

|---|---|

| Plate cleaner | ANTURA CtP Plate Cleaner |

| Washout gum | ANTURA CleanGum |

| Machine finisher | Unifin Plus |

| Baking gum | RC510 |

| Fountain solution | Energy Elite Pro is compatible with all ECO3 fountain solutions |

| IPA | ANTURA IPA 100 |

| Roller and blanket washes | Energy Elite Pro is compatible with all ECO3 roller & blanket washes |