This innovative system recycles process water that is used to wash out aqueous MAGIS P-Eco flexo plates.

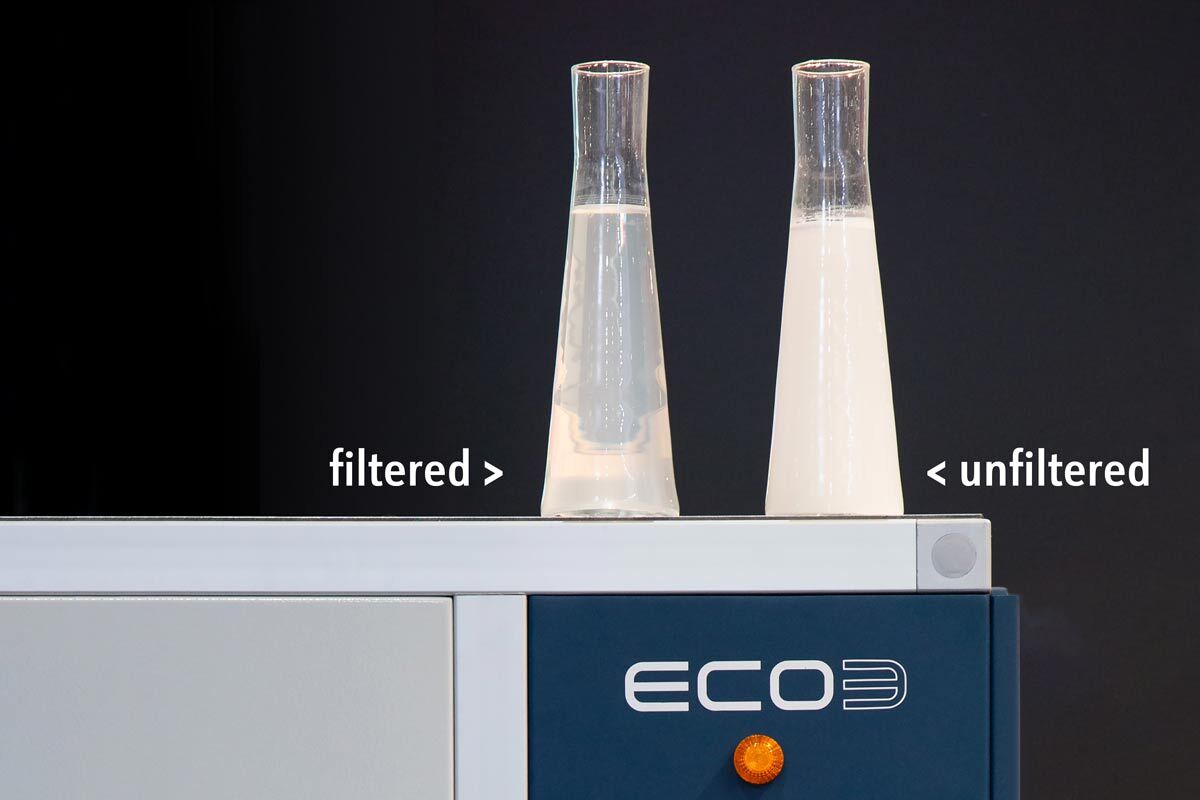

The closed-loop filtration system removes all the solid content from the washout water without using any chemicals. By filtering and returning the wash solution to the processor, this operator-friendly system significantly minimizes waste and resources use in flexo plate-making.

Benefits

Closed loop system

Water from the plate processor is filtered and returned to the processor, minimizing waste and resource use

Minimal energy consumption

The ReFlow unit requires only 1.5 KW nominal during cleaning cycles, reducing your energy bills and environmental impact.

Simplified waste management

MAGIS Eco ReFlow produces dry waste that is easy to handle and can be disposed of in regular waste systems. The waste that is generated totals around 0.16 kilo per processed square meter of flexo plate.

Easy to use

MAGIS Eco ReFlow offers fully automatic operations for seamless, hassle-free processing.

Enduring water cycle

The ReFlow unit facilitates a long-lasting water cycle, permitting continuous plate-making without frequent water changes.

Consistent quality

The filtering process ensures stable saturation of the washout solution for consistently high-quality plate washouts.

| MAGIS Eco ReFlow | |

|---|---|

| Capacity mixer tank for filter media | 70 L |

| Capacity buffer tank for untreated water | 15 L |

| Capacity buffer tank for filtered water | 15 L |

| Drum filtering surface | 0.1 m² / 1 ft² |

| Dimensions | - Length: 1,930 mm (75.98”) - Width: 1,130 mm (44.49”) - Height: 1,980 mm (77.95”) |

| Weight | 445 Kg |

| Power supply | 230V P + N + Gnd : 10 A |

| Rated power | 2.5 KW |

| Connections | - Compressed air (Requires: 6 bars / 10CFM) - Water |

| Conformity | - 2006/42 EG; 2011/30/EU: EN 50581; 2014/30/EU: 55032:+ EN 55024; 2014/35/EU: EN 60950-1 - UL Std. 60950-1; Cert to CSA Std. C22.2 N°60950-1; UL Std. 60950-1; Cert to CSA Std. C22.2 N°60950-1 |